|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series DewPoint-Compass®: Prediction of Dew Point Temperatures and the Risk of Dew Point Corrosion

The Ultimate Software Solution To Costly Dew Point Corrosion

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins |

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of DewPoint-Compass Software for Dew Point Corrosion Prediction |

|

|

DewPoint-Compass is the only device and OS independent software tool on the market for the prediction of dew point temperatures of flue gases and the risks of dew point corrosion. Design engineers, process engineers, maintenance and inspection engineers, and consultants can quickly determine the dew point temperatures of flue gases and the dew point corrosion rate, anytime, anywhere, on any device running any OS without the need to install or download anything. DewPoint-Compass also predicts the modes of condensation (mist condensation, film condensation or both), the concentration of the first condensed acid at the dew point temperature, the risk ranking of dew point corrosion, and the dew point corrosion rate for carbon steels, stainless steels and nickel alloys.

Figures below show the screen shots of DewPoint-Compass.

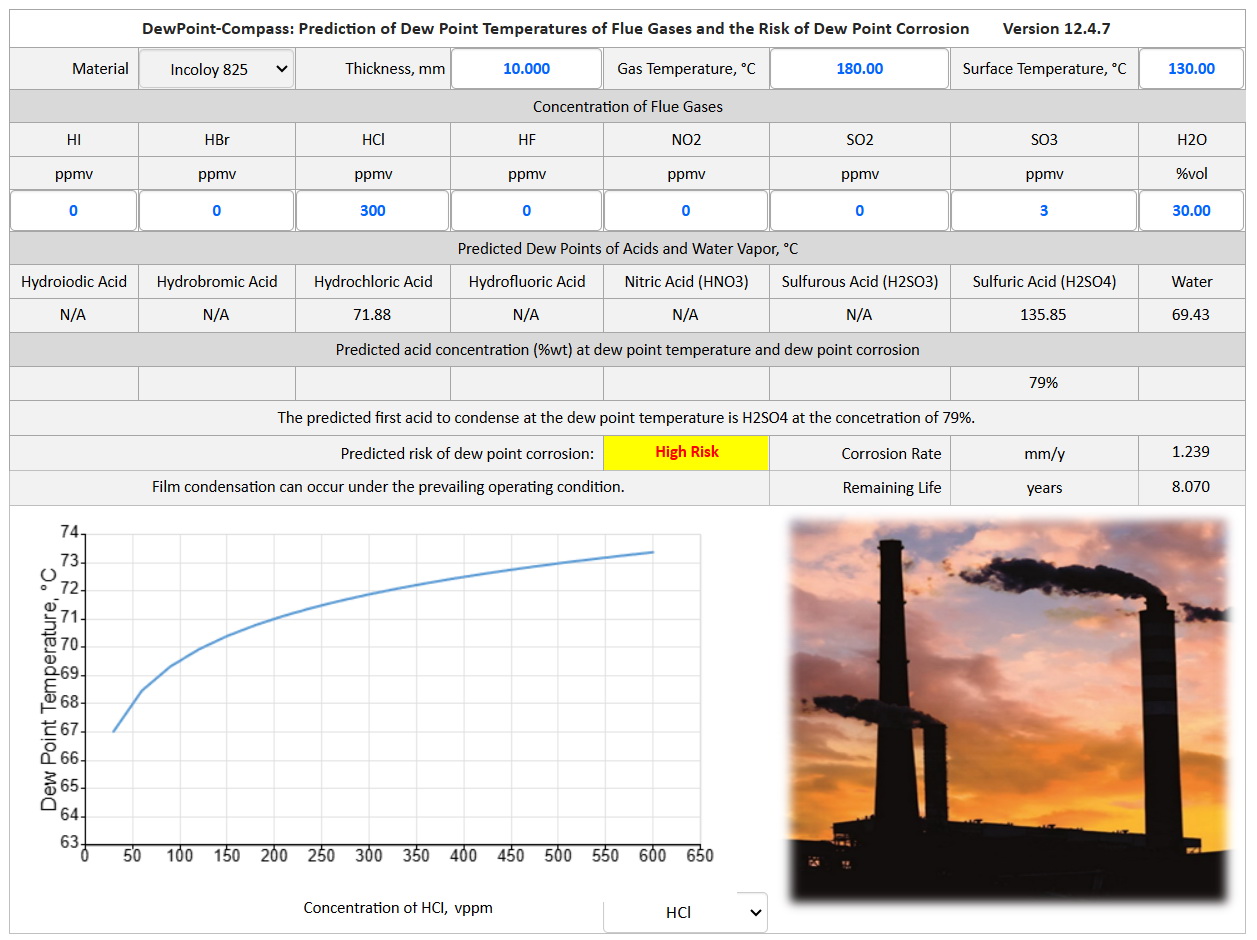

Figure 1 DewPoint-Compass Predicts the dew point temperatures of flue gases and the risk of dew point corrosion.

Under the prevailing operating conditions shown in Figure 1 above, the dew point temperatures of flue gases including SO3, SO2, HCl, HBr, HF, NO2, and water vapor are predicted. The predicted dew point temperature for hydrogen chloride gas (HCl) is 71.88°C and the predicted dew point temperature for sulfur trioxide (SO3) is 135.85°C. Dew-Point-Compass also predicts that the first condensed acid is sulfuric acid and its concentration is 79%. The risk of dew point corrosion at the prevailing operating conditions is predicted to be "high" and that the mode of condensation is film condensation on the internal wall surface of equipment/structure. The predicted dew point corrosion rate for the nickel alloy is 1.239 mm/y, and the remaining life is 8.07 years.

The effect of the concentration of the flue gases on the dew point temperature is plotted at the bottom left of the screen. Users of DewPoint-Compass can quickly assess the impact of flue gas composition on the risk of dew point corrosion.

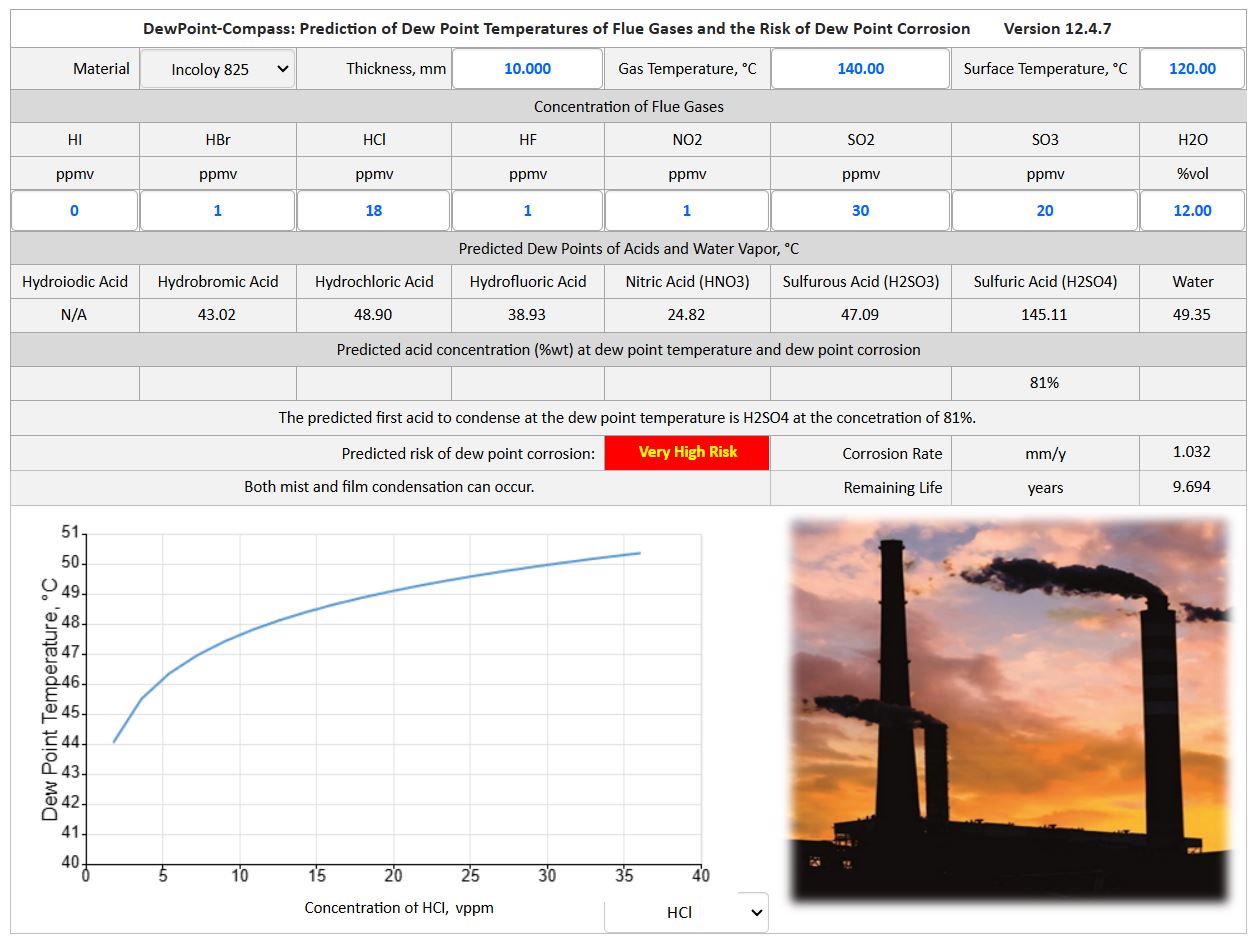

Under the prevailing operating conditions in Figure 2, DewPoint-Compass predicts that both mist and film condensation can occur to the equipment/structure and the risk of dew point corrosion is "very high".

Figure 2 DewPoint-Compass Predicts Dew Point Temperatures and The Modes of Condensation.

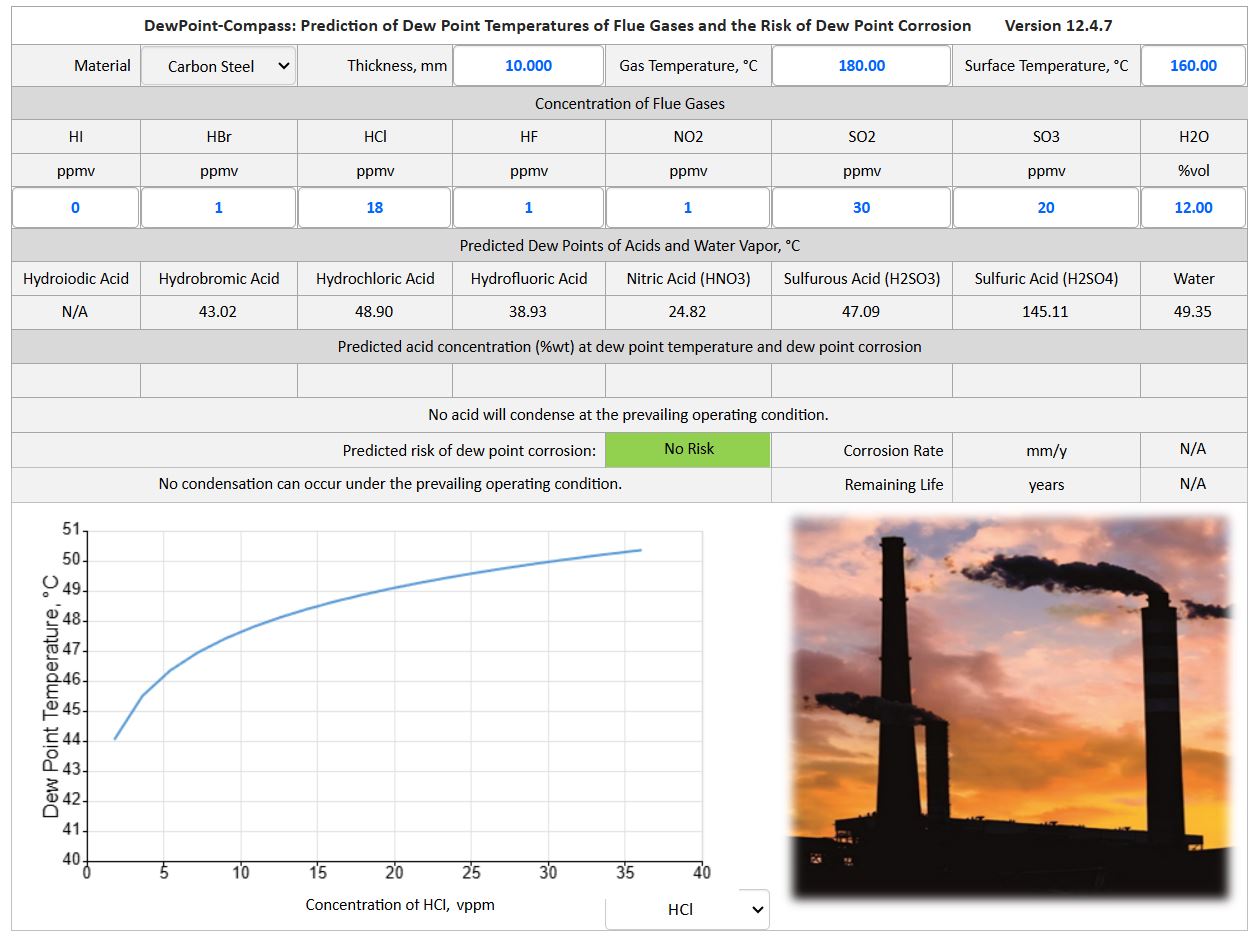

Under the prevailing operating conditions shown in Figure 3, there is no risk of dew point corrosion.

Figure 3 DewPoint-Compass Predicts Dew Point Temperatures and The Risk of Dew Point Corrosion.

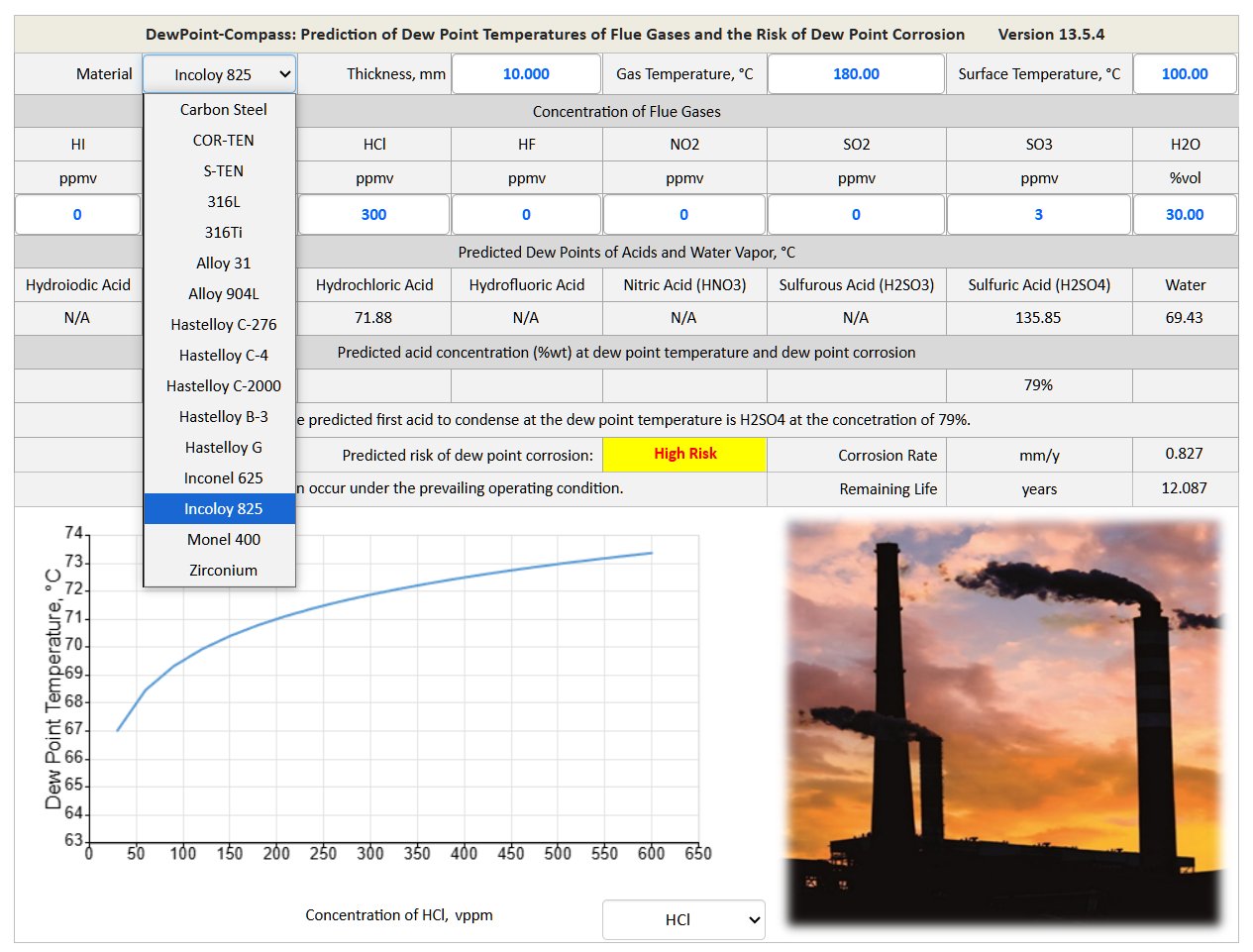

DewPoint-Compass is a powerful software tool for design engineers in their selection of materials for resistance to dew point corrosion (Figure 4). The following materials are available in DewPoint-Compass software: Carbon Steel

COR-TEN

316Ti If you cannot find the material of your interest in the above list, do let us know through the Contact Us link and we will conduct the necessary research and update the software database with your material, free of charge for licensed users of DewPoint-Compass.

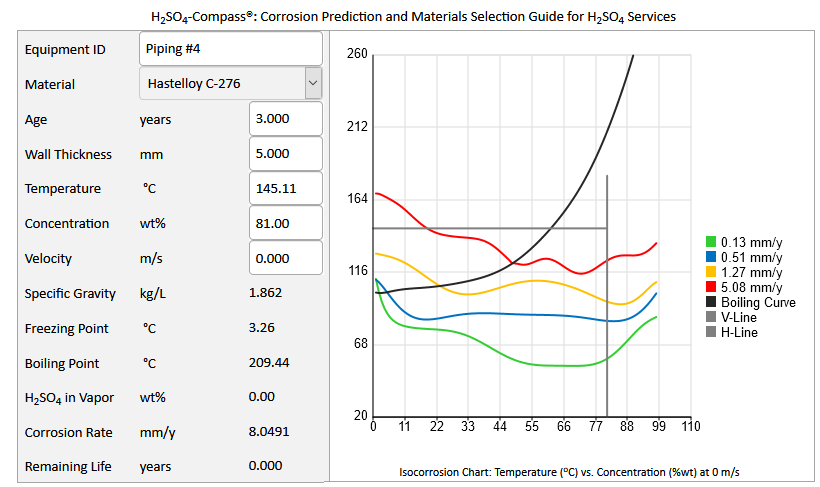

Figure 4 DewPoint-Compass for Assessment and Evaluation of Materials for Their Resistance to Dew Point Corrosion. Since DewPoint-Compass predicts both the dew point temperature and the concentration of the first condensed acid, it integrates seamlessly with H2SO4-Compass and/or HCl-Compass for the materials selection and the prediction of the corrosion rate. For example, under the prevailing operating conditions in Figure 2 above, the dew point temperature of SO3 is 145.11°C and that the first condensed sulfuric acid (H2SO4) is 81%. Using these numbers as inputs in H2SO4-Compass (Figure 5), the corrosion rate of alloy C-276 at the dew point temperature is predicted to be 8.049 mm/y. Please refer to this link for details on H2SO4-Compass.

Figure 5 DewPoint-Compass Integrates with H2SO4-Compass to Predict the Rate of Dew Point Corrosion.

The powerful applications of DewPoint-Compass are truly unlimited in engineering design, dew point corrosion prediction and dew point corrosion risk assessment, materials selection, trouble-shooting process-related issues and failure analysis of components and systems.

Click here to contact us for licensing details and experience the power of DewPoint-Compass. |

|

DewPoint-Compass, giving you the right directions in Dew Point Prediction and Dew Point Corrosion Risk Assessment |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2025. All rights reserved. |