|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series Seawater-Compass®: Seawater Corrosion Prediction for Metals & Alloys The Effective Software Solutions to Seawater Corrosion Version 12.4

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training

& Support |

CorrCompass |

|

|

Overview of Seawater-Compass Seawater-Compass models and predicts the corrosion rate and remaining service life for metals and alloys used in seawater services. Seawater-Compass is the only device and OS independent software tool on the market for the modeling and life prediction of seawater corrosion of metals and alloys including carbon steels, aluminum alloys, brass, copper-nickel alloys, nickel alloys, stainless steels, duplex stainless steels, and titanium alloys. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine: (1) the seawater corrosion rate of the selected metal or alloy; (2) the remaining life of the equipment or component; (3) the major forms of corrosion expected in seawater services, (4) the cautious notes on (a) the high risk of stress corrosion cracking (SCC) when the temperature exceeds the threshold; (b) the risk of erosion corrosion and cavitation when the seawater velocity is high; (c) the risk of pitting, crevice corrosion, and microbiologically-influenced corrosion (MIC) when the velocity is too low.

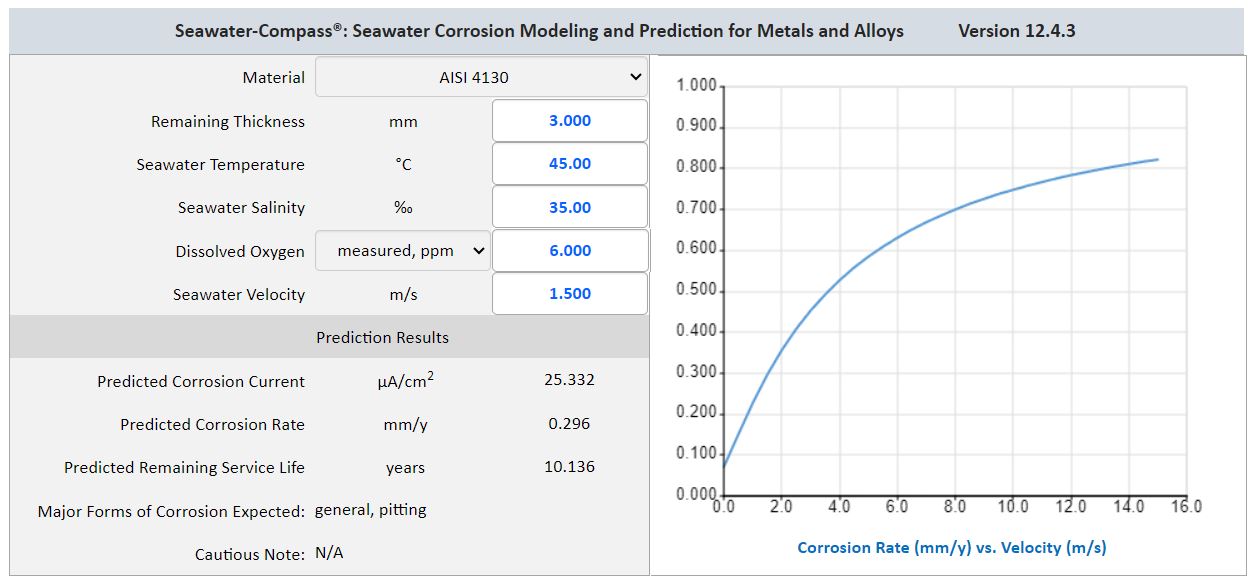

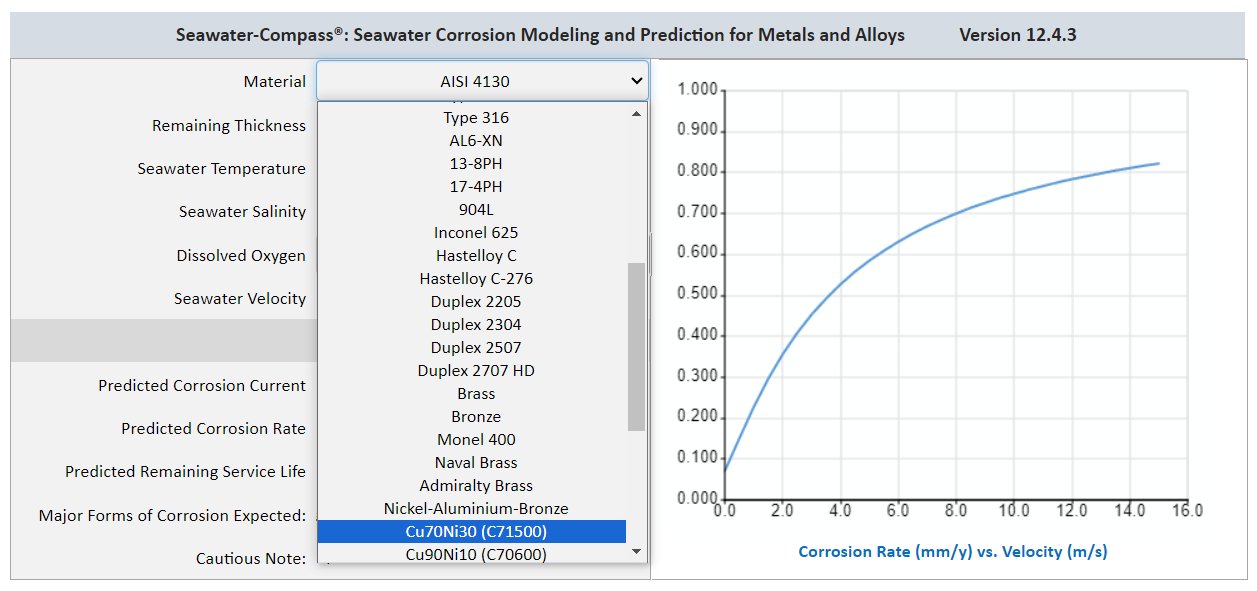

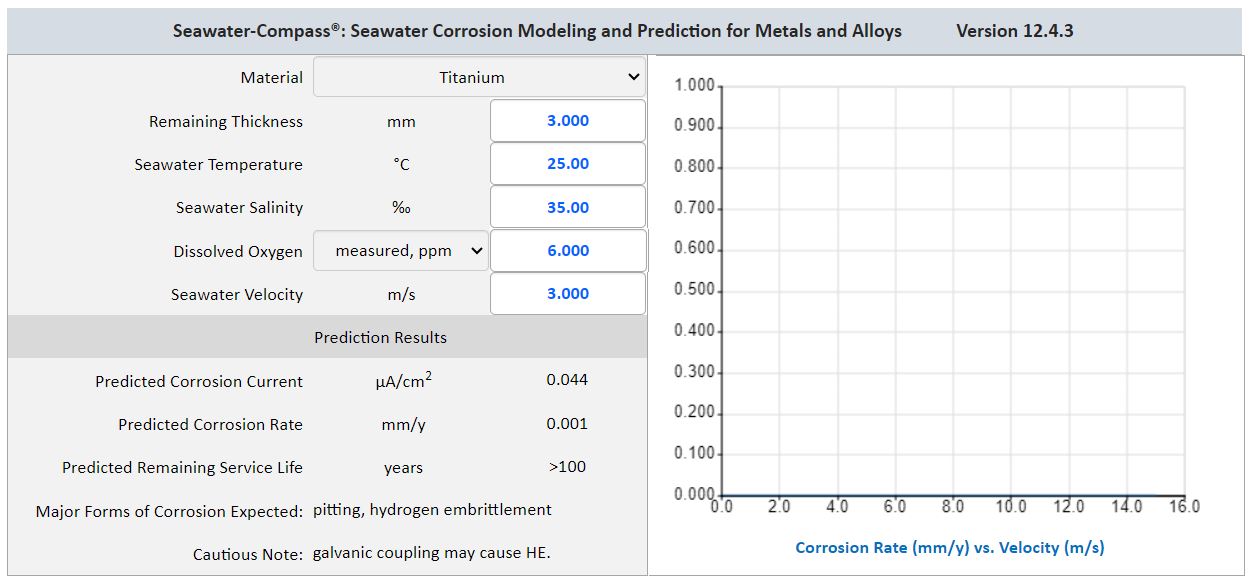

Figure 1 below shows an overview of Seawater-Compass. Users simply select one of the 50 metals and alloys from the list (Figure 2). Seawater-Compass models the effects of seawater temperature, seawater salinity, dissolved oxygen concentration, and seawater velocity on the seawater corrosion and predicts the corrosion rate and the remaining life of equipment or component under the prevailing operating conditions.

Figure 1 Overview of the Seawater-Compass for Predictive Modeling of Seawater Corrosion of Metals and Alloys

Seawater-Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything. Experience the industry's first cross-platform and device-independent seawater corrosion modeling and prediction app on your iPads, tablets, smart phones, notebooks and desktops, at any time and anywhere, in the office or in the field. No installation files to download, no browser plug-ins required, no USB dongles to carry around, and no license keys to transfer from one PC to another. Seawater-Compass simply works on any device running any OS. All you need is an internet browser.

In the application example in Figure 1 above, the predicted corrosion rate of carbon steel in seawater of salinity of 35‰ is 0.296 mm/y at the operating temperature of 45°C and seawater velocity of 1.5 m/s. Seawater-Compass predicts that the major forms of corrosion expected is general attack and pitting under the prevailing operating conditions.

Figure 2 Seawater-Compass: A Predictive Corrosion Software Tool for Materials Selection for Seawater Services

Using Seawater-Compass is as easy as 1-2-3.

(1) Select the material from the dropdown list and enter the design data (Figures 1 & 2)

(2) Enter the seawater data

(3) Review the prediction results

Seawater-Compass has the following materials in the selection list. If you cannot find the material of your interest, contact us and we will conduct the necessary tests and add that material to the selection list, free of charge for licensed users.

AA1100

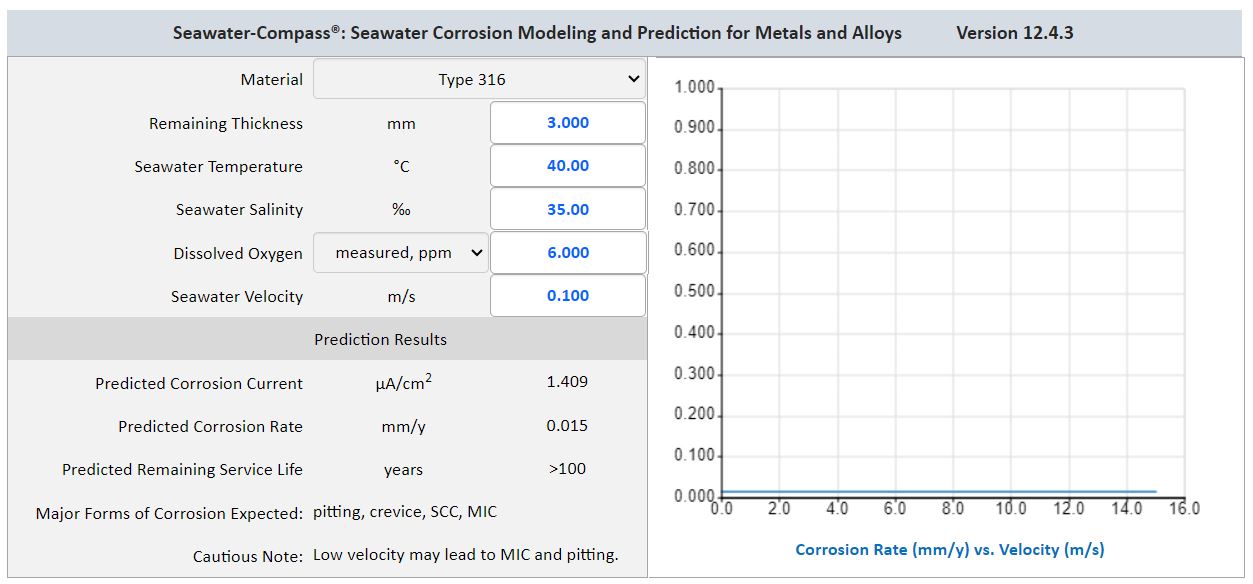

Figure 3 Seawater-Compass predicts the risk of pitting and microbiologically-influenced corrosion (MIC) under low flow or stagnant condition.

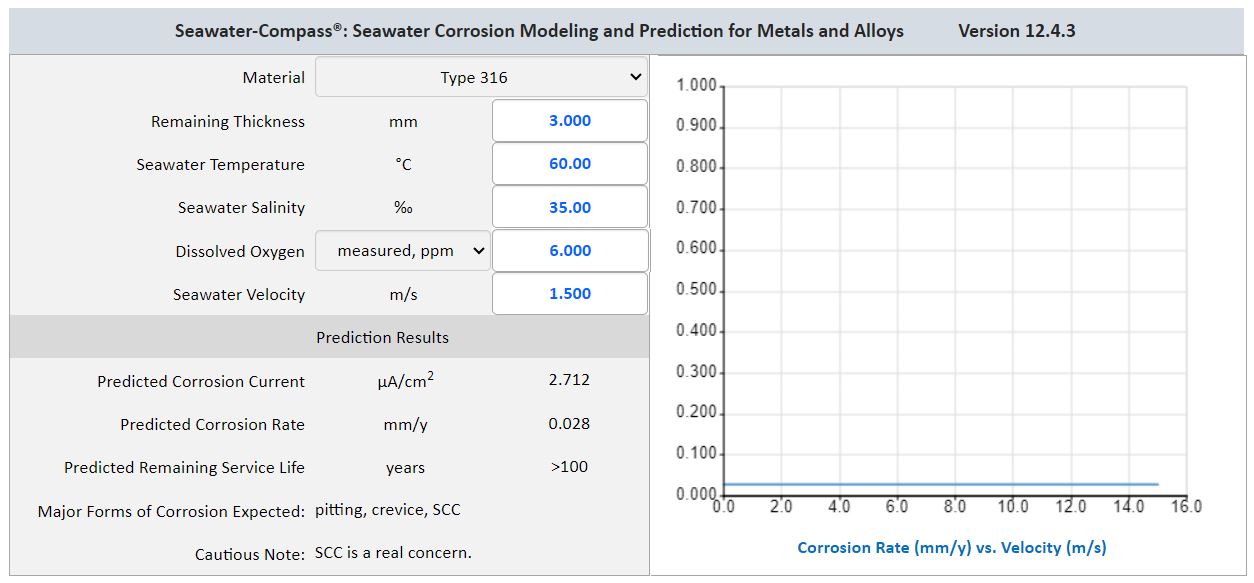

In Figure 3 above, the seawater velocity is low, at 0.1 m/s. Seawater-Compass predicts the risk of pitting and MIC with a cautious note for the user. In Figure 4 below, the seawater temperature is high at 60°C, Seawater-Compass predicts the risk of chloride stress corrosion cracking (SCC) for type 316 stainless steel. In Figure 5, Seawater-Compass predicts the risk of hydrogen embrittlement for titanium in seawater services.

Figure 4 Seawater-Compass predicts the risk of stress corrosion cracking (SCC) of austenitic stainless steels in seawater services.

Figure 5 Seawater-Compass predicts the risk of hydrogen embrittlement (HE) of Titanium in seawater services.

|

|

|

Seawater-Compass, giving you the right directions in Seawater Corrosion Modeling and Prediction. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2025. WebCorr Corrosion Consulting Services. All rights reserved. |