|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series MIC-Compass®: Modeling and Prediction of Microbiologically Influenced Corrosion in Oil and Gas Pipelines High-Value Software Solutions to Costly Corrosion Version 12.4

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins |

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training

& Support |

CorrCompass |

|

|

MIC-Compass is the only device and OS independent software tool on the market for the prediction and modeling of microbiologically influenced corrosion (MIC) in oil and gas pipelines. Pipeline engineers, consultants, operation personnel, maintenance and inspection engineers can quickly assess the MIC risk, identify the dominating corrosion process in the pipeline (be it MIC or other types of corrosion such as CO2 corrosion, H2S corrosion, CO2-H2S mixed corrosion, and oxygen corrosion), and determine the corrosion rates under the prevailing operating conditions. MIC-Compass works on any device running any OS without the need to install or download anything.

The presence of bacteria in the water/deposit samples collected from a pipeline does not necessarily mean that MIC will occur in the pipeline and the absence of bacteria in the water/deposit samples does not necessarily mean that MIC will not occur in the pipeline. There is no single factor that can trigger the initiation of MIC. The initiation and the growth rate of MIC are determined by a number of factors working in synergy:

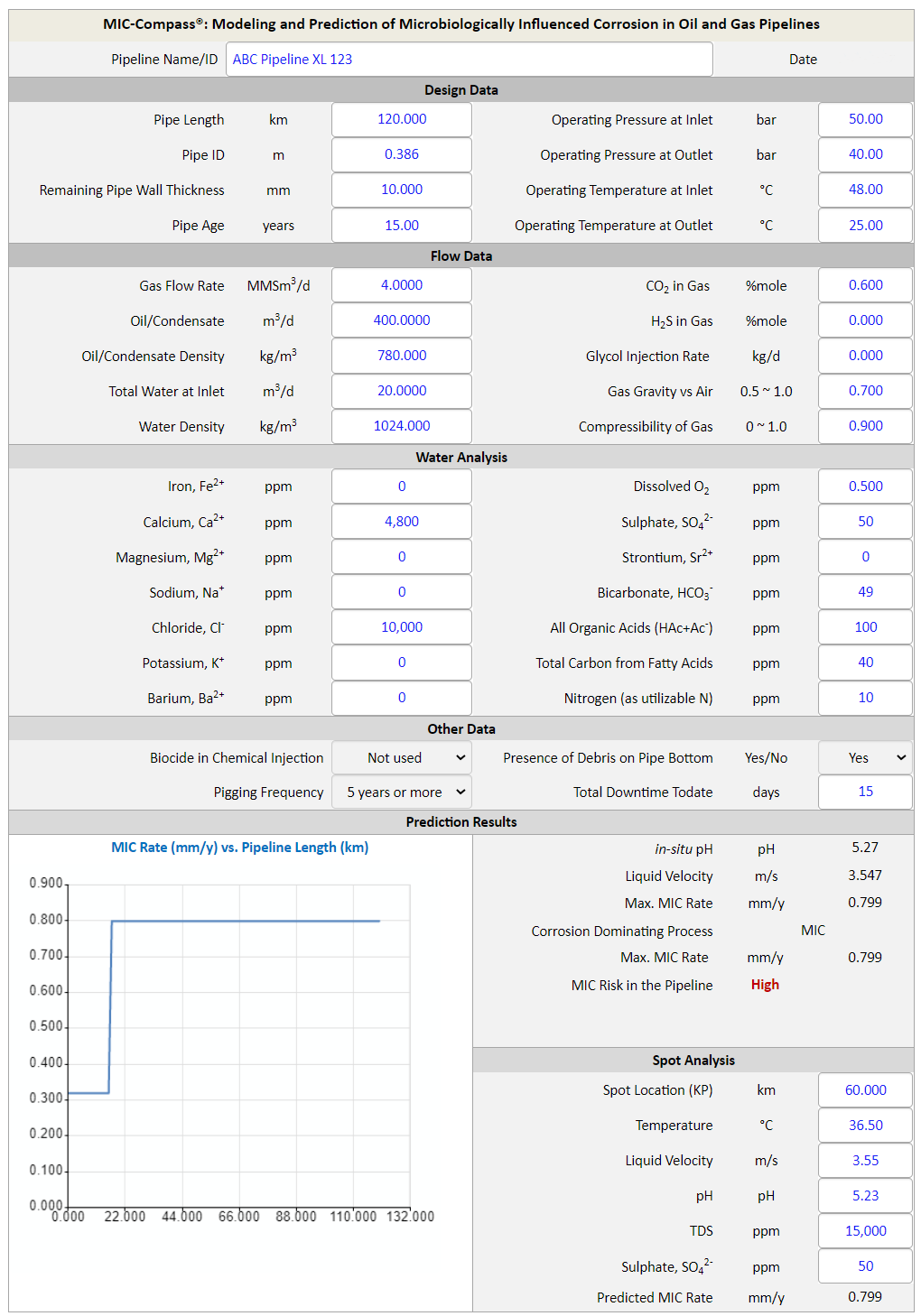

Figures below demonstrate the operation of MIC-Compass. MIC-Compass has a built-in in-siu pH calculator that determines the in-situ pH under the prevailing operating temperature and pressure. The pH reported from water analysis conducted by testing labs at room temperature and pressure is not the "in-situ" pH. It is the "in-situ" pH that matters in MIC and other types of corrosion such as CO2 corrosion in oil and gas pipelines.

Figure 1 MIC-Compass Predicts the MIC risk and the corrosion rate in oil and gas pipelines

Based on the users' inputs of the prevailing operating conditions, MIC-Compass assesses the critical conditions for microbiologically influenced corrosion and other different types of corrosion, and determines the dominating corrosion process in the pipeline. The prediction results include the following:

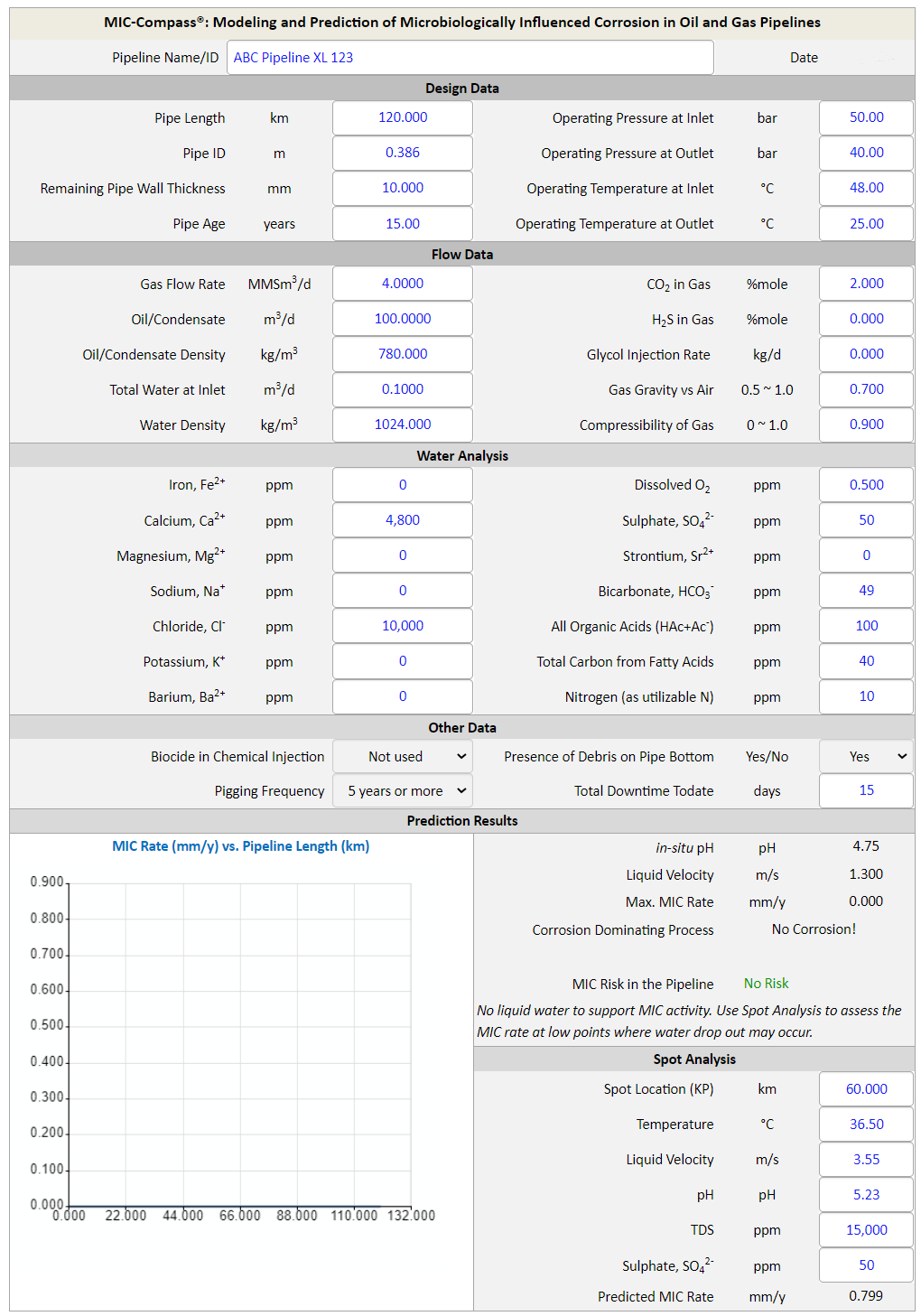

Figure 2 MIC-Compass assesses the critical conditions for microbiologically influenced corrosion. No water, no corrosion!

Using the "Spot Analysis" function, users can quickly assess the MIC rate at low points along a pipeline where water drop out may occur. Under the prevailing operating conditions in Figure 2 above, liquid water is generally not expected in the pipeline as the gas phase is under-saturated with water. However, at river crossings or some low points along the pipeline length, water drop out may occur. MIC-Compass gives users the power to assess the what-if scenarios.

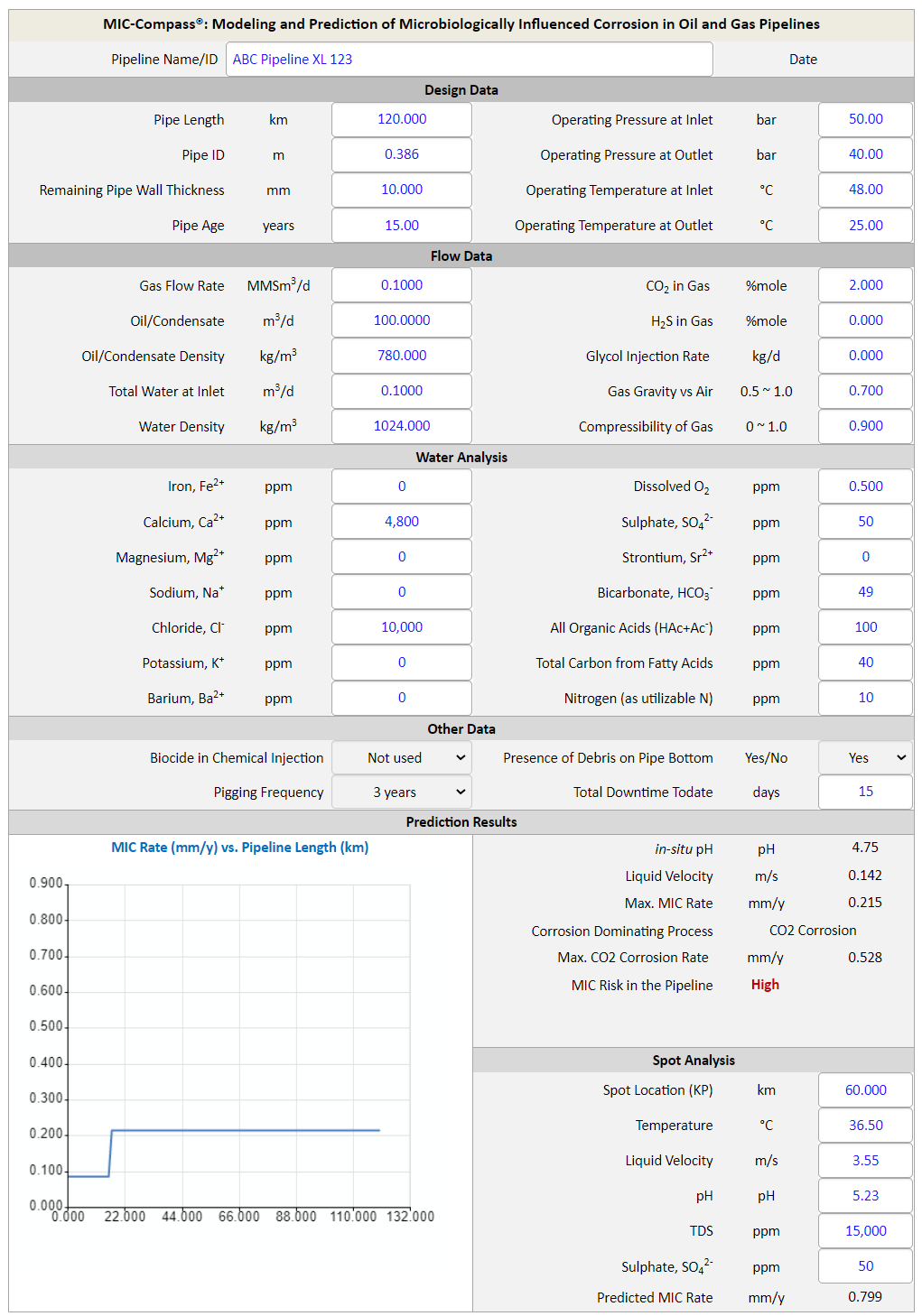

Figure 3 MIC-Compass predicts that carbon dioxide corrosion is the corrosion dominating process under the prevailing operating conditions.

Under the prevailing operating conditions in Figure 3, MIC-Compass identifies CO2 corrosion as the dominating corrosion process and the maximum CO2 corrosion rate in the pipeline is 0.528 mm/y while the MIC growth rate is predicted to be 0.215 mm/y. The spot analysis at the user selected pipeline location gives a MIC growth rate of 0.799 mm/y.

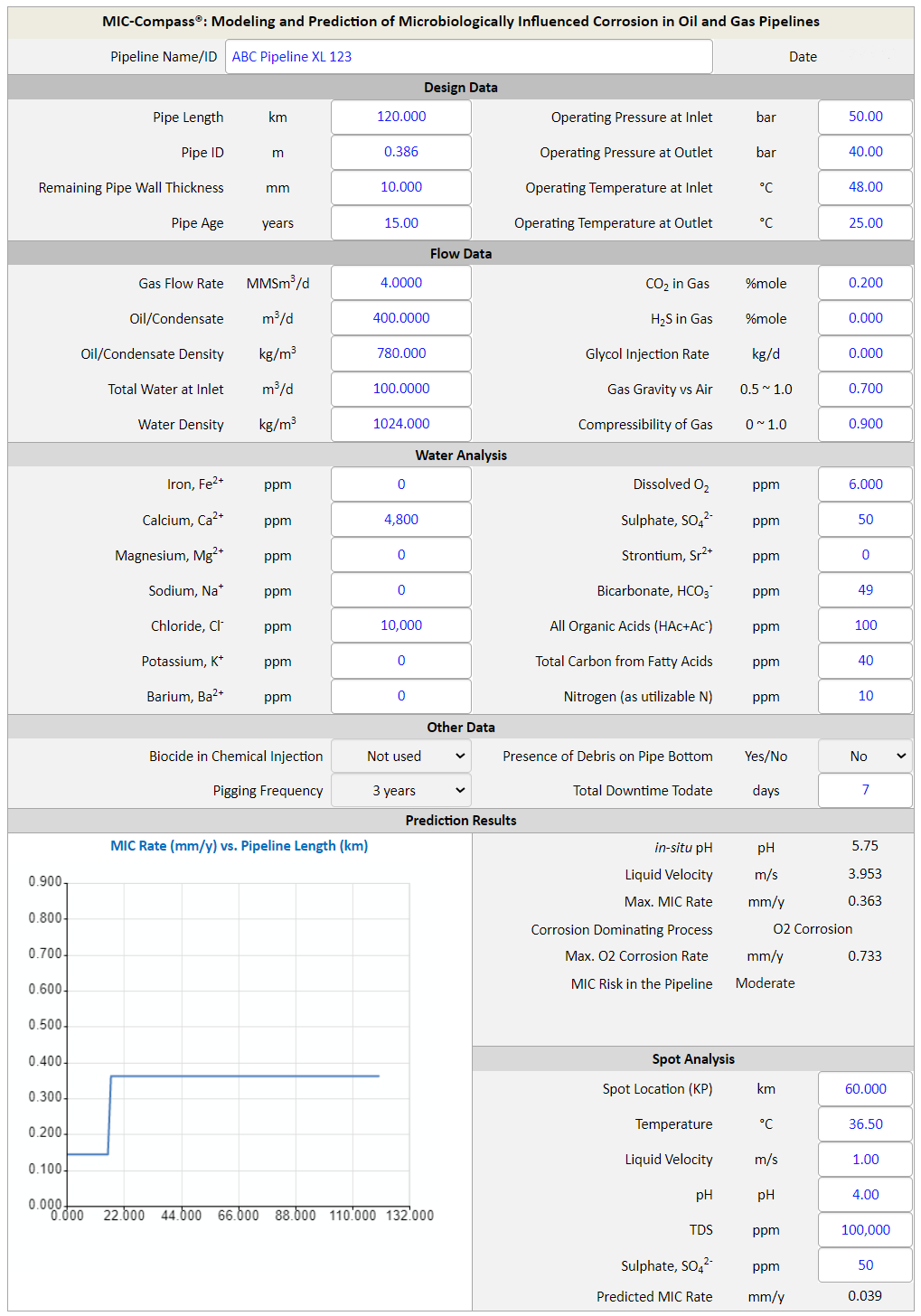

Figure 4 MIC-Compass predicts oxygen corrosion is the corrosion dominating process under the prevailing operating conditions.

Under the prevailing operating conditions in Figure 4 above, MIC-Compass identifies oxygen corrosion as the dominating corrosion process and the maximum O2 corrosion rate is 0.733 mm/y while the maximum MIC growth rate is 0.363 mm/y.

MIC-Compass is a powerful software tool for internal corrosion direct assessment and pipeline integrity management. Both prevailing and historical pipeline operating data can be used to model and predict the growth rates of microbiologically influenced corrosion and other different type of corrosion mechanisms (CO2 corrosion, H2S corrosion, CO2-H2S mixed corrosion, O2 corrosion) in oil and gas pipelines.

Click here to contact us for licensing details and experience the power of MIC-Compass. |

|

|

MIC-Compass, giving you the right directions in the modeling and prediction of Microbiologically Influenced Corrosion. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2025. WebCorr Corrosion Consulting Services. All rights reserved. |