|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | ||

|

Course Outline | Who Should Attend | Registration | In-House | On-Demand | Online Courses | PPT Slides+Testbank |Course List | Why WebCorr |

||

| Course Overview | ||

|

This 5-day corrosion short course is available for in-house training, on-site training, online and distance learning worldwide. It can also be customized to meet the specific needs of your organization.

|

||

|

||

| Course Outline | ||

|

1. Introduction to Integrity Operating Windows (IOWs)

2. Corrosion: Basic Concepts and Terminology

3. Basic Metallurgy and the Impact of Temperature on Microstructures and Mechanical Properties

3.1 Understanding the

Atomic Structure of Metals

4.1 Effect of

Temperature

5. Integrity Operating Widows: Work Process

6. Integrity Operating Widows: Risk Ranking

7. Examples of Integrity Operating Widows

9. General Considerations for Establishing IOWs and Their Limits

10. Documenting, Implementing, and Training on Established IOWs

11. Monitoring and Measuring IOW Parameters

12. Updating IOWs

13. Roles, Responsibilities, and Accountabilities for IOWs

14. Integrating IOWs with Other Related Work Processes

15. Examples of Potential Process Parameters for IOWs for Generic Process Units

17. Example of an IOW Development for a Heat Exchanger

18. Case Study: Implementation of IOWS in a gas processing plant

19.

Corrosion Prediction and Corrosion

Modeling Software for Calculation

and Verification of IOWs

O2Compass: Modeling and Prediction of High Temperature Oxidation and Creep Damage

NAC-Compass: Modeling and Prediction of High Temperature Naphthenic Acid Corrosion

CP-Compass: Cathodic Protection Design Calculations, Verification, Assessment and

Solutions

PipelineCompass: Pipeline Corrosion Modeling, Prediction, Assessment and Solutions

SC-Compass: Stray Current

Corrosion and AC Corrosion - Identification, Assessment and

Prediction

GC-Compass: Galvanic Corrosion Prediction and Materials Compatibility Assessment

CUI-Compass: Prediction and Risk Assessment of Corrosion Under Insulation and Fireproofing

Atmosphere-Compass: Prediction and Modeling of Atmospheric

Corrosion of Metals and Alloys 20. End-of-Course Examination

|

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List |

||

| Who Should Attend | ||

|

Designers, engineers, inspection and maintenance personnel who are concerned with corrosion under insulation in the various industries such as chemical process, refining, petrochemical, power, onshore and offshore industries.

|

||

| Registration for This Corrosion Course | ||

|

|

||

| In-House Training Corrosion Courses/On-Site Training Corrosion Courses | ||

|

There is no minimum or maximum number of participants required for in-house training corrosion courses. We conduct the in-house training corrosion course at your company's premises and at a time convenient to your company.

Click here to contact us for a quotation.

|

||

| Corrosion Course-On-Demand | ||

|

Click here to contact us for a quotation for taking this course as course-on-demand.

|

||

| Online and Distance Learning Corrosion Courses | ||

|

Click here to register this corrosion short course for online or distance learning. |

||

| PowerPoint Slides and Test Banks for Trainers, Instructors, Tutors, University Lecturers and Professors | ||

|

If you are involved in teaching or training, you may wish to purchase a complete set of the trainer's package for this training course. The trainer's package comes complete with ready-to-use PowerPoint slides (fully editable) and test bank (with answer keys). These ready-to-use PowerPoint slides contain high quality color photographs, illustrations, animations, audio and video clips. The test bank contains questions conveniently grouped into four categories: (1) true or false, (2) multiple choice, (3) calculation, and (4) reasoning and open-ended discussions. The trainer's package is suitable for in-house training and university teaching (30 lecture hours). This is exactly the same package that WebCorr uses to deliver our current training course. The one-time lump sum fee allows your organization to use the training package and also modify it. For example, your organization may modify the course contents and re-name/re-brand the course under your organization’s name. WebCorr only retains the copyright of the original PowerPoint slides and test banks.

Click here to contact us if you need more information on the trainer's package. |

||

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List |

||

|

Copyright © 1995-2024 WebCorr Corrosion Consulting Services. All rights reserved. |

||

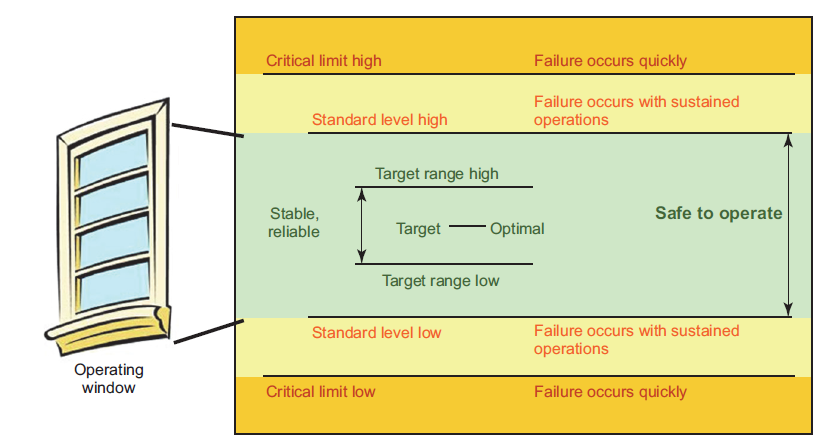

Corrosion

is defined in the ASTM G193 standard as “the deterioration of a

material, usually a metal, that results from a chemical or

electrochemical reaction with its environment”. The 66 damage mechanisms

described in API 571 are either due to metallurgical and

micro-structural changes occurring at high operating temperatures (high

temperature corrosion) or the changes in chemistry such as pH,

concentration of corrosives, fluid velocity at low/ambient temperatures

(aqueous corrosion). For process safety, a set of critical operating

ranges and limits must be established for key process variables. The

establishment, implementation, and maintenance of integrity operating

windows (IOWs) are essential for maintaining the integrity and reliability of

pressure equipment. This 5-day advanced course aims to (1) provide

participants with a clear and thorough understanding of why and how

operating variables affect the metallurgical, microstructural,

mechanical, and corrosion resistant properties of common alloys; (2) to

explain the common damage mechanisms encountered in the refining, petrochemical,

and process industries; (3) to explain the importance of integrity

operating windows (IOW’s) for process safety management, and (4) to

guide users in how to establish and implement an IOW program for the

refining, petrochemical, and process facilities. A number of the

Corrosion

is defined in the ASTM G193 standard as “the deterioration of a

material, usually a metal, that results from a chemical or

electrochemical reaction with its environment”. The 66 damage mechanisms

described in API 571 are either due to metallurgical and

micro-structural changes occurring at high operating temperatures (high

temperature corrosion) or the changes in chemistry such as pH,

concentration of corrosives, fluid velocity at low/ambient temperatures

(aqueous corrosion). For process safety, a set of critical operating

ranges and limits must be established for key process variables. The

establishment, implementation, and maintenance of integrity operating

windows (IOWs) are essential for maintaining the integrity and reliability of

pressure equipment. This 5-day advanced course aims to (1) provide

participants with a clear and thorough understanding of why and how

operating variables affect the metallurgical, microstructural,

mechanical, and corrosion resistant properties of common alloys; (2) to

explain the common damage mechanisms encountered in the refining, petrochemical,

and process industries; (3) to explain the importance of integrity

operating windows (IOW’s) for process safety management, and (4) to

guide users in how to establish and implement an IOW program for the

refining, petrochemical, and process facilities. A number of the

If you are concerned with corrosion in your

business, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all corrosion courses can

be customized to fit your organization's needs.

If you are concerned with corrosion in your

business, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all corrosion courses can

be customized to fit your organization's needs.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you on an one-on-one basis at a time and a location convenient to you. This option costs significantly less than a full-scale in-house training program.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you on an one-on-one basis at a time and a location convenient to you. This option costs significantly less than a full-scale in-house training program. All our corrosion short courses are

available for online or offline distance learning. You can start an

online course at any time and learn at your

own comfortable pace, whenever and wherever you are. You have around-the-clock

access to interactive and media-rich course materials, virtual labs, course

instructions, course assignments, and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM or DVD or USB memory stick for offline learning.

All our corrosion short courses are

available for online or offline distance learning. You can start an

online course at any time and learn at your

own comfortable pace, whenever and wherever you are. You have around-the-clock

access to interactive and media-rich course materials, virtual labs, course

instructions, course assignments, and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM or DVD or USB memory stick for offline learning.