|

|

|

Home |

Consulting |

Training |

Expert Witness |

Failure Analysis |

Design Review |

Corrosion Test |

Corrosion Software |

Protective Coatings |

Materials Selection |

Cathodic Protection |

>>> |

|

Hot Dip Galvanizing

& Mechanical Plating

- Processes, Properties and Applications |

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

Why WebCorr

|

|

Course Overview |

|

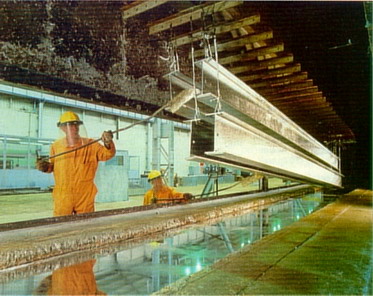

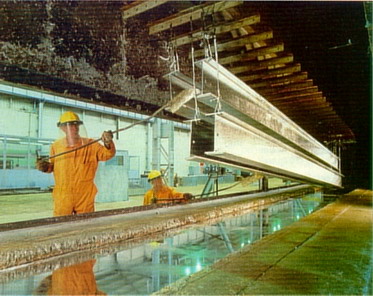

This 3-day short course systematically and thoroughly covers every aspect of hot

dip galvanizing and mechanical plating, from the process to the properties and applications of

galvanized coatings and mechanical plating. The course covers design, specification, painting

of galvanic steel surfaces, fabrication methods including bolting and

welding, inspection, coating life prediction, maintenance and repair of

galvanized products. The course will help designers, specifiers,

materials engineers, consultants, and fabricators to protect and improve

their steel products. This corrosion short course can be taken as

in-house training course, online course and distance learning course

worldwide. It can also be customized to meet the specific needs of your

organization. This 3-day short course systematically and thoroughly covers every aspect of hot

dip galvanizing and mechanical plating, from the process to the properties and applications of

galvanized coatings and mechanical plating. The course covers design, specification, painting

of galvanic steel surfaces, fabrication methods including bolting and

welding, inspection, coating life prediction, maintenance and repair of

galvanized products. The course will help designers, specifiers,

materials engineers, consultants, and fabricators to protect and improve

their steel products. This corrosion short course can be taken as

in-house training course, online course and distance learning course

worldwide. It can also be customized to meet the specific needs of your

organization.

|

|

|

|

Course Outline |

|

|

1 Corrosion & The Need for Galvanizing

1.1 The economic, social, political and environmental impacts

1.2 Liabilities due to corrosion

1.3 History of galvanizing

1.4 Basic

concepts in corrosion

1.5 Terminologies and conventions

1.6 Why do metals corrode

1.7 How do metals corrode

1.9 Corrosion prevention methods

1.10 Galvanic corrosion and properties of zinc and steel

1.11 Cathodic protection

1.12 The need for galvanizing

2

Process, Properties and Applications

2.1 Galvanizing fundamentals

2.1.1

The different galvanizing processes

2.1.2

Galvanized coating characteristics

2.2 Principles of venting

2.3 Basic venting rules

2.4 Principles of draining

2.5 Basic draining rules

2.6 Principles of avoiding distortion

2.7 Galvanizing rules to avoid distortion

2.8 Basic rules - design for galvanizing

2.9 Metallurgy of the galvanizing process

2.10 Factors affecting galvanizing quality and service

2.10.1 Steel

surface condition

2.10.2 Steel

metallurgy

2.10.3 Weld quality

2.11 Mechanical properties of galvanized coatings

2.11.1 Strength and

ductility

2.11.2

Embrittlement

2.11.3 Fatigue

strength

2.12 Other metallic zinc coatings for steel

2.13 Continuous galvanizing processes

2.14 Protective life of zinc coatings

2.14.1 Performance

in various environments

2.14.2

Compatibility of galvanized coatings with various media

2.14.3 Transport

and storage of galvanized products

2.14.4 Surface

(iron) contamination of galvanized products

2.14.5 Protection

of cut edges and damaged areas

2.14.6 Corrosion

rate of galvanized coatings

2.15 Reliability of coatings for steel

2.16 Galvanized coatings for buildings and structural steel

2.17 Galvanizing of fasteners and small components

2.20 Marking for identification

2.21 Properties and applications of

Zn-Al-Mg-Si

alloy hot-dip galvanized coatings

3

Design, Specification and Inspection of Galvanized Products

3.1 Size and shape of articles to be galvanized

3.2 Materials suitable for galvanizing

3.3 Design and fabrication of components for galvanizing

3.4 Dimensional stability

3.5 Galvanized coatings on threaded parts

3.6 Galvanized coatings on moving parts

3.7 Design for maximum corrosion protection

3.8 Metallurgical aspect of design

3.9 Inspection of work before dispatch to galvanizer

3.10 Standard specification for hot dip galvanized coatings

3.11 Standards for galvanized products

3.12 Inspection of galvanized products

3.12.1 Hot dip

galvanized coating defects: causes and remedies

3.12.2 Steel

defects and their effects on galvanized coatings

3.12.3 Defects in

paint coatings

3.13 Variations in appearance and their relationship to coating

quality

3.14 Non-destructive testing for coating thickness

3.15 Reconditioning damaged galvanized surfaces

4

Bolting Galvanized Steel

4.1 Zinc coating for fasteners

4.2 Influence of galvanized coatings on design

4.3 Slip factors

4.4 Structural bolts and bolting technique

4.5 Design for bolted structural joints

4.6 Applications of high strength bolts

4.7 Tightening procedures for high strength bolts

4.8 Inspection of high strength bolted joints

5 Welding Galvanized Steel

5.1 GMA welding

5.1.1 Effect of welding

position

5.1.2 GMA braze welding

5.1.3 GMA spot welding

5.2 Manual metal arc welding

5.3 GTA welding

5.4 Carbon arc welding

5.5 Torch welding

5.6 Reconditioning weld-damaged surfaces

5.7 Welding fumes

6 Painting Galvanized Steel

6.1 Painting galvanized steel - duplex coatings

6.2 Economics of painting galvanized steel

6.3 Synergistic effect of duplex systems

6.4 Painting procedures

6.5 Adhesion

6.6 Preparation of galvanized surfaces for painting

6.7 Pretreatment systems

6.8 Specialized primers

6.9 Finish coats

6.10 Painting recommendations

7 Mechanical Plating

7.1 Introduction to

Mechanical Plating

7.2 Hydrogen Embrittlement and Mechanical Plating

7.3 Mechanical Plating Process Description

7.4 Typical Process Sequence for Mechanical Plating

7.5 Barrel Loading Capacity for Typical Parts

7.6 Mechanical Plating Typical Cycle

7.7 Parts Suitable for Mechanical Plating

7.8 Typical Mechanical Plating Layout

7.9 Mechanical Plating Equipment

7.10 Budgetary Costs for Mechanical Plating Systems

7.11 Automation for Mechanical Plating

7.12 Post-treatments for Mechanical Plating

8 Glossary of

Galvanizing Terms

9 End-of-Course Exam

|

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Who Should Attend |

|

-

Hot-dip galvanizing operators who are concerned with the operation issues in

ho-dip galvanizing.

-

Designers, specifiers, materials engineers, consultants, and fabricators who

are concerned with corrosion of steel and are interested in hot-dip

galvanizing technology for protecting steel products.

-

Engineers and technicians who are involved in testing, inspection, analysis

of galvanized steel products.

-

Users of galvanized steel products who are concerned with the performance

and durability of hot-dip galvanized steel.

|

|

Registration

for This Corrosion Course |

-

Click

here to register for this corrosion course online,

or

-

Click

here to download this corrosion course brochure with

registration form in PDF format.

|

|

In-House Training Corrosion Courses |

|

If you are concerned with corrosion in your

business, in-house training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all corrosion courses can

be customized to fit your organization's needs.

There is no minimum or maximum number of participants required for

in-house training corrosion courses. We conduct the in-house training

corrosion course at your company's premises and at a time convenient to

your company. Requests for in-house training corrosion courses from overseas countries are also welcome.

Click

here to contact us

for a quotation. |

|

Corrosion

Course-On-Demand |

|

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you on an one-on-one basis at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house training program.

Click

here to contact us for a quotation for

taking this course as course-on-demand.

|

|

Online and Distance Learning Corrosion

Courses |

|

All corrosion courses can be conducted

through online or distance learning. An username and password will be

emailed to course participants for accessing the online course

materials. Alternatively, a CD-ROM containing the same online course

material or a master hard copy of corrosion course notes can be

sent to your organization. Instructions,

course assignments, discussions and questions related to the corrosion courses

are posted on the website. Free email support for online courses is

provided for a period up

to 12 months. A Certificate of Completion will be issued to participants

who pass the online test with a score of 70% and above.

Click

here to register this

corrosion short course for online or distance learning. |

|

|

|

PowerPoint Slides and Test Banks for Trainers,

Instructors, Tutors, University Lecturers and Professors |

|

If you are involved in teaching or

training, you may wish to purchase a complete set of the trainer's

package for this training course. The trainer's

package comes complete with ready-to-use PowerPoint slides (fully

editable) and test bank (with answer keys). These ready-to-use

PowerPoint slides contain high quality color photographs, illustrations,

animations, audio and video clips. The test bank contains questions

conveniently grouped into four categories: (1) true or false, (2)

multiple choice, (3) calculation, and (4) reasoning and open-ended

discussions. The trainer's package is suitable for in-house training and

university teaching (30 lecture hours). This is exactly the same package that WebCorr uses to deliver our

current training course.

The one-time lump sum fee allows your

organization to use the training package and also modify it. For

example, your organization may modify the course contents and

re-name/re-brand the course under your organizationís name. WebCorr only

retains the copyright of the original PowerPoint slides and test banks.

Click

here to contact us if you need more information on the trainer's package. |

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Home |

Contact Us |

Copyright

©

1995-2026.. All rights reserved. |

This 3-day short course systematically and thoroughly covers every aspect of hot

dip galvanizing and mechanical plating, from the process to the properties and applications of

galvanized coatings and mechanical plating. The course covers design, specification, painting

of galvanic steel surfaces, fabrication methods including bolting and

welding, inspection, coating life prediction, maintenance and repair of

galvanized products. The course will help designers, specifiers,

materials engineers, consultants, and fabricators to protect and improve

their steel products. This corrosion short course can be taken as

in-house training course, online course and distance learning course

worldwide. It can also be customized to meet the specific needs of your

organization.

This 3-day short course systematically and thoroughly covers every aspect of hot

dip galvanizing and mechanical plating, from the process to the properties and applications of

galvanized coatings and mechanical plating. The course covers design, specification, painting

of galvanic steel surfaces, fabrication methods including bolting and

welding, inspection, coating life prediction, maintenance and repair of

galvanized products. The course will help designers, specifiers,

materials engineers, consultants, and fabricators to protect and improve

their steel products. This corrosion short course can be taken as

in-house training course, online course and distance learning course

worldwide. It can also be customized to meet the specific needs of your

organization.