|

|

|

Home |

Consulting |

Training |

Expert Witness |

Failure Analysis |

Design Review |

Corrosion Test |

Corrosion Software |

Protective Coatings |

Materials Selection |

Cathodic Protection |

>>> |

|

Preferential Weld Corrosion: Causes and Prevention |

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

Why WebCorr

|

|

Course Overview |

|

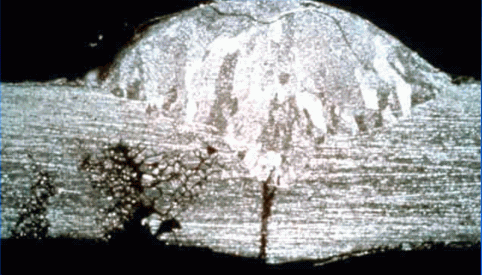

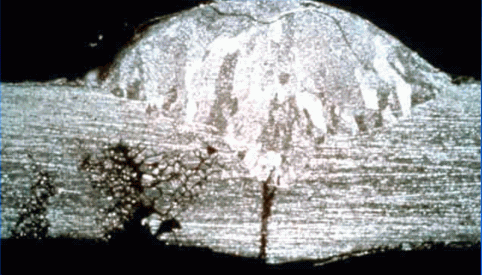

Welding

plays an essential role in the fabrication of components and structures

such as reactor vessels, pipe work, heat exchangers etc. The associated

local heating and cooling can significantly affect the corrosion

resistance of the material. A welded joint constitutes a significant

discontinuity in a structure from the compositional, metallurgical, and

mechanical viewpoints. In many situations it is the performance of

welded joints that determines the useful service life of the component

or structure. This 3-day advanced course covers the causes of different

forms of preferential weld corrosion and the practical methods of

prevention. Welding

plays an essential role in the fabrication of components and structures

such as reactor vessels, pipe work, heat exchangers etc. The associated

local heating and cooling can significantly affect the corrosion

resistance of the material. A welded joint constitutes a significant

discontinuity in a structure from the compositional, metallurgical, and

mechanical viewpoints. In many situations it is the performance of

welded joints that determines the useful service life of the component

or structure. This 3-day advanced course covers the causes of different

forms of preferential weld corrosion and the practical methods of

prevention.

This corrosion short course is

available for in-house training, online and distance learning worldwide.

It can also be customized to meet the specific needs of your

organization.

|

|

|

|

Course Outline |

|

|

|

1. Introduction to Corrosion

2. Overview of Preferential Weld Corrosion

3. Weldment Metallurgy and Preferential Weld Corrosion

3.1 Effect of Welding on Corrosion

3.1.1 Factors affecting weldment corrosion

3.1.2 Methods of welding

3.1.3 Welding austenitic SS vs carbon steel

3.1.4 Residual stress and stress concentration

3.1.5 Weld defects

3.1.6 Weld metallurgy

3.1.7 Weld metal composition

3.1.8 Iron contamination: its effects & removal

3.1.9 Heat tint: its effects & removal

3.1.10 Summary of fabrication defects

3.2 Precipitation of intermetallics (sigma, chi & Laves phases)

in stainless steels

3.2.1 Microstructural features in SS

3.2.2 Precipitation of delta ferrite and Schaeffler Diagram

3.2.3 Alpha prime phase and 475°C embrittlement

3.2.4 Precipitation of intermetallics:

submicroscopic sigma, chi and Laves phases

3.2.5 Chemical compositions of various intermetallics and phases

3.2.6 Time-Temperature-Precipitation diagrams for

sigma, chi and Laves phases and carbides

3.2.7 Effect of chemical composition on sigma precipitation

3.2.8 Effect of Nitrogen on sigma precipitation

3.2.9 Effect of cold working on sigma precipitation

3.2.10 Invisible (submicroscopic) sigma/chi phases and their effects on corrosion

3.2.11 Time-temperature-precipitation curves for various austenitic stainless

steels: precipitation of carbides, sigma, chi and Laves phases

3.3 Intergranular corrosion, weld decay and knifeline attack

3.3.1 Sensitization of austenitic stainless steels

3.3.2 Cr profile along the grain boundaries

3.3.3 Effect of carbon, molybdenum and nitrogen on

time-temperature- precipitation diagrams

3.3.4 Effect of cold working and applied stress

3.3.5 Sensitization of Ferritic Stainless Steels

3.3.6 Sensitization of Duplex Stainless Steels

3.3.7 Effect sulfide inclusions in stainless steels

3.3.8 Ferritic and duplex stainless steels

3.3.9 Nickel-chromium alloys

3.3.10 Aluminum alloys

3.3.11 Weld decay and knifeline attack on austenitic stainless steels

3.4 Why is weldment

particularly susceptible to microbiologically influenced corrosion?

3.5 Preferential Weld Corrosion of Various Alloy Systems

3.5.1 Austenitic stainless steels

3.5.2 Ferritic stainless steels

3.5.3 Nickel alloys

3.5.4 Duplex stainless steels

3.5.5 Carbon steels

3.5.6. Aluminum

3.6 Preferential Weld Corrosion in CO2 and H2S

Environments

4. Guidelines for the Prevention, Control, and Monitoring of

Preferential Weld Corrosion

5. Case Studies

6. End-of-course examination

|

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Who Should Attend

This Corrosion Course |

|

Corrosion practitioners, failure analysis

personnel, designers, technical managers, inspection and maintenance engineers,

reliability and integrity engineers, coatings and weld inspectors, quality

control personnel.

|

|

Registration

for This Corrosion Course |

|

Click

here to register for this corrosion course online,

or

Click

here to download this corrosion course brochure with

registration form in PDF format.

|

|

In-House Training Corrosion Courses and

On-Site Training Corrosion Course |

|

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs. If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

There is no limit to the number of participants required for

in-house training corrosion courses. We conduct the in-house training

corrosion course at your company's premises worldwide, and at a time convenient to

your company.

Click

here to contact us

for a quotation for in-house training corrosion courses. |

|

Corrosion

Course-On-Demand |

|

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program. All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

Click

here to contact us for a quotation. |

|

Online

Corrosion Courses and Distance Learning Corrosion

Courses |

|

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning. All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

Click

here to to register an online corrosion short course. |

|

|

|

PowerPoint Slides and Test Banks for Trainers,

Instructors, Tutors, University Lecturers and Professors |

|

If you are involved in teaching or

training, you may wish to purchase a complete set of the trainer's

package for this training course. The trainer's

package comes complete with ready-to-use PowerPoint slides (fully

editable) and test bank (with answer keys). These ready-to-use

PowerPoint slides contain high quality color photographs, illustrations,

animations, audio and video clips. The test bank contains questions

in four categories: (1) true or false, (2)

multiple choice, (3) calculation, and (4) reasoning and open-ended

discussions. The trainer's package is suitable for in-house training and

university teaching. This is exactly the same package that WebCorr uses to deliver our

current training course.

The one-time lump sum fee allows your

organization to use the training package and also modify it. For

example, your organization may modify the course contents and

re-name/re-brand the course under your organization’s name. WebCorr only

retains the copyright of the original PowerPoint slides and test bank.

Click

here to contact us if you need more information on the trainer's package.

|

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Home |

Contact Us |

Copyright

©

1995-2026.. All rights reserved. |

Welding

plays an essential role in the fabrication of components and structures

such as reactor vessels, pipe work, heat exchangers etc. The associated

local heating and cooling can significantly affect the corrosion

resistance of the material. A welded joint constitutes a significant

discontinuity in a structure from the compositional, metallurgical, and

mechanical viewpoints. In many situations it is the performance of

welded joints that determines the useful service life of the component

or structure. This 3-day advanced course covers the causes of different

forms of preferential weld corrosion and the practical methods of

prevention.

Welding

plays an essential role in the fabrication of components and structures

such as reactor vessels, pipe work, heat exchangers etc. The associated

local heating and cooling can significantly affect the corrosion

resistance of the material. A welded joint constitutes a significant

discontinuity in a structure from the compositional, metallurgical, and

mechanical viewpoints. In many situations it is the performance of

welded joints that determines the useful service life of the component

or structure. This 3-day advanced course covers the causes of different

forms of preferential weld corrosion and the practical methods of

prevention.  If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program. All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.