|

|

|

Home |

Consulting |

Training |

Expert Witness |

Failure Analysis |

Design Review |

Corrosion Test |

Corrosion Software |

Protective Coatings |

Materials Selection |

Cathodic Protection |

>>> |

|

Environmental Cracking

(HB-HIC-SWC-SOHIC-SSC-SZC-HSC-HE-SCC): Recognition, Mechanisms and

Prevention |

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

Why WebCorr

|

|

Corrosion Course Overview |

|

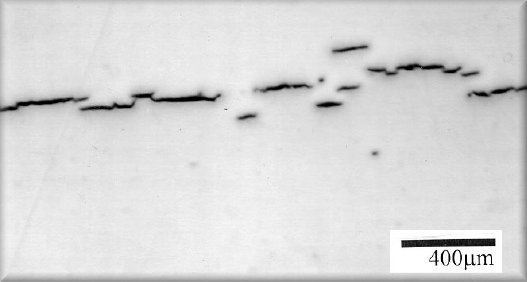

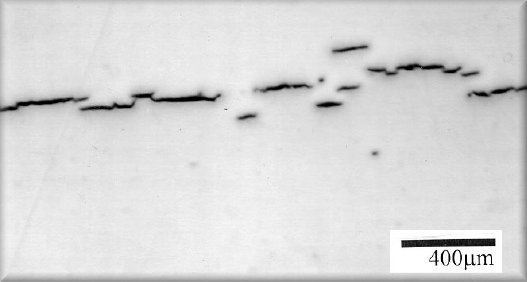

Environmental

Cracking is one of the key factors that can affect the structural

integrity or limit the life of metallic structures. Environmental

cracking is a general term that includes: stress corrosion cracking

(SCC), caustic cracking, liquid metal cracking, corrosion fatigue,

hydrogen blistering, hydrogen embrittlement (HE), hydrogen-induced

cracking (HIC), stepwise cracking (SWC), stress-oriented

hydrogen-induced cracking (SOHIC), sulfide stress cracking (SSC),

soft-zone cracking (SZC), and hydrogen stress cracking (HSC). Environmental

Cracking is one of the key factors that can affect the structural

integrity or limit the life of metallic structures. Environmental

cracking is a general term that includes: stress corrosion cracking

(SCC), caustic cracking, liquid metal cracking, corrosion fatigue,

hydrogen blistering, hydrogen embrittlement (HE), hydrogen-induced

cracking (HIC), stepwise cracking (SWC), stress-oriented

hydrogen-induced cracking (SOHIC), sulfide stress cracking (SSC),

soft-zone cracking (SZC), and hydrogen stress cracking (HSC).

This 5-day corrosion short course systematically and thoroughly covers

the recognition, mechanisms, test methods and prevention of the various

types of cracking phenomena. Also discussed in this corrosion short

course is the NACE MR0175/ISO 15156 standard for the selection of

crack-resistant materials for use in H2S-containing oil and gas

environments.

This corrosion course

is available for in-house training, online and distance learning

worldwide. It can also be customized to meet the specific needs of your

organization.

|

|

|

|

Corrosion Course Outline |

|

1. Introduction

2. Corrosion Basics

3. Overview of Environmental Cracking

4. HB-HIC-SWC-SOHIC-SSC-SZC-HSC-HE-SCC: Recognition, Mechanisms and

Prevention

4.1 Overview of Hydrogen Damage

4.2 Hydrogen Blistering (HB) and HIC-SWC

4.3 High Temperature Hydrogen Attack (HTHA)

4.4 Hydrogen Embrittlement

4.5 Hydride Embrittlement

4.6 Hydrogen Induced Cracking (HIC), Stepwise Cracking (SWC)

& SOHIC

4.6.1 Definition

4.6.2 Recognition

4.6.3 Mechanisms

4.6.4 Factors Influencing

HIC, SWC and SOHIC

4.6.4.1 Environmental Factors

4.6.4.2 Metallurgical Factors

4.6.5 Prevention and Control

4.7 Sulfide Stress Cracking (SSC) and Soft Zone Cracking

(SZC)

4.7.1 Definition

4.7.2 Recognition

4.7.3 Mechanisms

4.7.4 Factors Influencing

SSC and SZC

4.7.4.1 Environmental Factors

4.7.4.2 Metallurgical Factors

4.7.5 Prevention and Control

4.8 Hydrogen Stress Cracking (HSC) and Hydrogen Embrittlement

(HE)

4.8.1 Definition

4.8.2 Recognition

4.8.3 Mechanisms

4.8.4 Factors Influencing

HSC and HE

4.8.4.1 Environmental Factors

4.8.4.2 Metallurgical Factors

4.9 Stress Corrosion Cracking (SCC)

4.9.1 Definition of

Stress Corrosion Cracking

4.9.2 Recognition of

Stress Corrosion Cracking

4.9.3 Mechanisms of

Stress Corrosion Cracking

4.9.4 Factors Influencing

SCC

4.9.4.1 Environmental Factors

4.9.4.2 Metallurgical Factors

4.9.5 Prevention and Control

4.10 Stress Corrosion Cracking of Pipeline Steels

4.11 Comparison of HIC-SWC, SOHIC, SSC, SZC, HSC, HE and SCC

4.12 HIC-SOHIC-SSC-HSC-SCC Test Methods

4.13 Corrosion Fatigue and Liquid Metal Embrittlement

4.14 Computer Software Tools for Modeling and Prediction

of Environmental Cracking

5. Understanding NACE MR0175-ISO 15156

5.1 Objective

5.2 Background

5.2.1 Abbreviated Terms

5.3 NACE MR0175-ISO 15156 Interpretation and Maintenance

5.4 From NACE MR0175 to NACE MR0175-ISO15156

5.4.1 Significant changes

to previous MR0175:

5.4.1.1 Responsibilities for Various Users of the Document

5.4.1.2 Changes that affect only the Carbon Steel Alloys

5.4.1.3 Changes that affect only the Corrosion Resistant Alloys

5.4.1.4 Other Options for Material Qualifications

5.4.1.5 Requirements for Marking (Part 2, Section 9; Part 3, Section 7)

5.5 Structure of New Document

5.5.1 Part 1 - General

Principles for Selection of Cracking-Resistant Materials

5.5.1.1 Scope of the Standard - Equipment and Component Design (Section

1)

5.5.1.2 Service Conditions: Evaluation and Definition (Section 6)

5.5.1.3 Pre-Qualified Materials Selection Guide (Section 7)

5.5.1.4 Material Qualification Alternatives and Implementation

5.5.1.5 Materials Qualification Documentation (Section 9)

5.5.2 Part 2:

Cracking-Resistant Carbon and Low Alloy Steels

5.5.2.1 Scope of the Standard - Equipment and Component Design

5.5.2.2 Carbon and Low Alloy Steels in H2S environments (Section 6)

5.5.2.3 Qualification and Selection (Section 7)

5.5.2.4 Evaluation for resistance to HIC and SWC (Section 8)

5.5.2.5 Marking (Section 9)

5.5.3 Part 3:

Cracking-Resistant CRAs and Other Alloys

5.5.3.1 Scope of the Standard - Equipment and Component Design

5.5.3.2 Corrosion Resistant Alloys in H2S environments (Section 5)

5.5.3.3 Qualification and Selection (Section 6)

5.5.3.4 Purchasing Information and Marking (Section 7)

5.6 End Userís Application Guideline for MR0175/ISO 15156

5.6.1 Select

Qualification Method

5.6.1.1 Scope of MR0175-ISO 15156

5.6.1.2 Existing Facilities vs. New Projects

5.6.1.3 Existing Facilities

5.6.1.4 New Projects

5.6.1.5 Alternative Materials Qualification

5.6.2 Qualification

By Field Experience

5.6.2.1 Material Qualification by Field Experience

5.6.2.2 Describe and document the materials to be qualified

5.6.2.3 Describe and document the service environment

5.6.2.4 Compile the Service History for a minimum of 2 years

5.6.2.5 Inspection of the in-service material

5.6.2.6 Intended Service Environment

5.6.2.7 Report and file documentation

5.6.3 Qualification

by Laboratory Testing

5.6.3.1 Material Qualification by Laboratory testing

5.6.3.2 Select material type and refer to the applicable part of

NACE/ISO standard

5.6.3.3 Select the laboratory qualification option that best fits the

application

5.6.3.4 Identify the Qualification Required

5.6.3.5 Select the Test Method

5.6.3.6 Establish the Test Conditions

5.6.3.7 Specify the Acceptance Criteria for each test method

5.6.3.8 Report the Test Results

5.7 Other Issues

5.8 References

5.9 Questions (175) and interpretations for NACE MR0175-ISO

15156

5.10 Case Studies

6. End of Course Examination

|

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Who Should Attend This Corrosion Course |

|

Designers and engineers who are involved in the selection and evaluation of

materials for use in H2S-containing environments in oil and gas production.

Successful completion of this corrosion course helps participants prepare for

their NACE certification examinations at the Corrosion Technician, Corrosion

Technologist and Senior Corrosion Technologist levels.

|

|

Registration

for This Corrosion Course |

|

Click

here to register for this corrosion course online,

or

Click

here to download this corrosion course brochure with

registration form in PDF format.

|

|

In-House Training Corrosion Courses and On-Site Training

Corrosion Courses |

|

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs. If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

There is no limit to the number of participants required for

in-house training corrosion courses. We conduct the in-house training

corrosion course at your company's premises worldwide, and at a time convenient to

your company.

Click

here to contact us

for a quotation for in-house training corrosion courses.

|

|

Corrosion

Course-On-Demand |

|

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program. All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

Click

here to contact us for a quotation.

|

|

Online Corrosion Courses and Distance Learning Corrosion Courses |

|

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning. All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

Click

here to to register an online corrosion short course. |

|

|

|

Corrosion

Course-On-Webex |

|

Webex

is hosted by Cisco, a product purpose-built for real-time web

communications. If you are an existing user of Webex, or if you are

willing to experience the power of Webex, we can conduct the course for you

over Webex with audio and video presentations and interactions with the

course instructor and other course attendees in real-time. It is just

like the physical classroom settings that everyone can interact with each

other. Your questions will be answered in real time by our instructor. Webex

is hosted by Cisco, a product purpose-built for real-time web

communications. If you are an existing user of Webex, or if you are

willing to experience the power of Webex, we can conduct the course for you

over Webex with audio and video presentations and interactions with the

course instructor and other course attendees in real-time. It is just

like the physical classroom settings that everyone can interact with each

other. Your questions will be answered in real time by our instructor.

Click

here to contact us for a quotation.

|

|

PowerPoint Slides and Test Banks for Trainers,

Instructors, Tutors, University Lecturers and Professors |

|

If you are involved in teaching or

training, you may wish to purchase a complete set of the trainer's

package for this training course. The trainer's

package comes complete with ready-to-use PowerPoint slides (fully

editable) and test bank (with answer keys). These ready-to-use

PowerPoint slides contain high quality color photographs, illustrations,

animations, audio and video clips. The test bank contains questions

in four categories: (1) true or false, (2)

multiple choice, (3) calculation, and (4) reasoning and open-ended

discussions. The trainer's package is suitable for in-house training and

university teaching (30 lecture hours). This is exactly the same package that WebCorr uses to deliver our

current training course.

The one-time lump sum fee allows your

organization to use the training package and also modify it. For

example, your organization may modify the course contents and

re-name/re-brand the course under your organizationís name. WebCorr only

retains the copyright of the original PowerPoint slides and test bank.

Click

here to contact us if you need more information on the trainer's package.

|

|

Course Outline |Who Should Attend |Registration |In-House |On-Demand |Online Courses |PPT Slides+Testbank |Course List

|

|

Home |

Contact Us |

Copyright

©

1995-2025.. All rights reserved. |

Environmental

Cracking is one of the key factors that can affect the structural

integrity or limit the life of metallic structures. Environmental

cracking is a general term that includes: stress corrosion cracking

(SCC), caustic cracking, liquid metal cracking, corrosion fatigue,

hydrogen blistering, hydrogen embrittlement (HE), hydrogen-induced

cracking (HIC), stepwise cracking (SWC), stress-oriented

hydrogen-induced cracking (SOHIC), sulfide stress cracking (SSC),

soft-zone cracking (SZC), and hydrogen stress cracking (HSC).

Environmental

Cracking is one of the key factors that can affect the structural

integrity or limit the life of metallic structures. Environmental

cracking is a general term that includes: stress corrosion cracking

(SCC), caustic cracking, liquid metal cracking, corrosion fatigue,

hydrogen blistering, hydrogen embrittlement (HE), hydrogen-induced

cracking (HIC), stepwise cracking (SWC), stress-oriented

hydrogen-induced cracking (SOHIC), sulfide stress cracking (SSC),

soft-zone cracking (SZC), and hydrogen stress cracking (HSC). If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

If you are concerned with corrosion in your

company, in-house training or on-site training is a great solution to train a group of

employees from design, production, operation, quality assurance, inspection

and maintenance, and technical sales and support on corrosion control and

corrosion prevention technology. The contents of all our corrosion courses can

be customized to fit your organization's needs.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you

(on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house

or on-site corrosion training program. All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning.

All

our corrosion short courses are available for online or offline distance

learning. You can start an online corrosion course at any time and learn

at your own comfortable pace and schedule, whenever and wherever you

are. You have around-the-clock access to the interactive and media-rich

course materials, virtual labs, course instructions and course assessments. Discussions and questions related to the corrosion courses

are posted on the website or exchanged through email for a period up to 3 months. Video conferencing or instant messaging can also be arranged for discussions of course topics.

For those who do not have ready access to internet, we can send

you our online course materials on a CD-ROM, or DVD, or USB flash drive for offline

distance learning. Webex

is hosted by Cisco, a product purpose-built for real-time web

communications. If you are an existing user of Webex, or if you are

willing to experience the power of Webex, we can conduct the course for you

over Webex with audio and video presentations and interactions with the

course instructor and other course attendees in real-time. It is just

like the physical classroom settings that everyone can interact with each

other. Your questions will be answered in real time by our instructor.

Webex

is hosted by Cisco, a product purpose-built for real-time web

communications. If you are an existing user of Webex, or if you are

willing to experience the power of Webex, we can conduct the course for you

over Webex with audio and video presentations and interactions with the

course instructor and other course attendees in real-time. It is just

like the physical classroom settings that everyone can interact with each

other. Your questions will be answered in real time by our instructor.