|

Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Why WebCorr|Course Outline|Who Should Attend|Registration|In-House |On-Demand |Online Courses |On Webex|PPT Slides+Testbank |Course List |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Course Overview | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

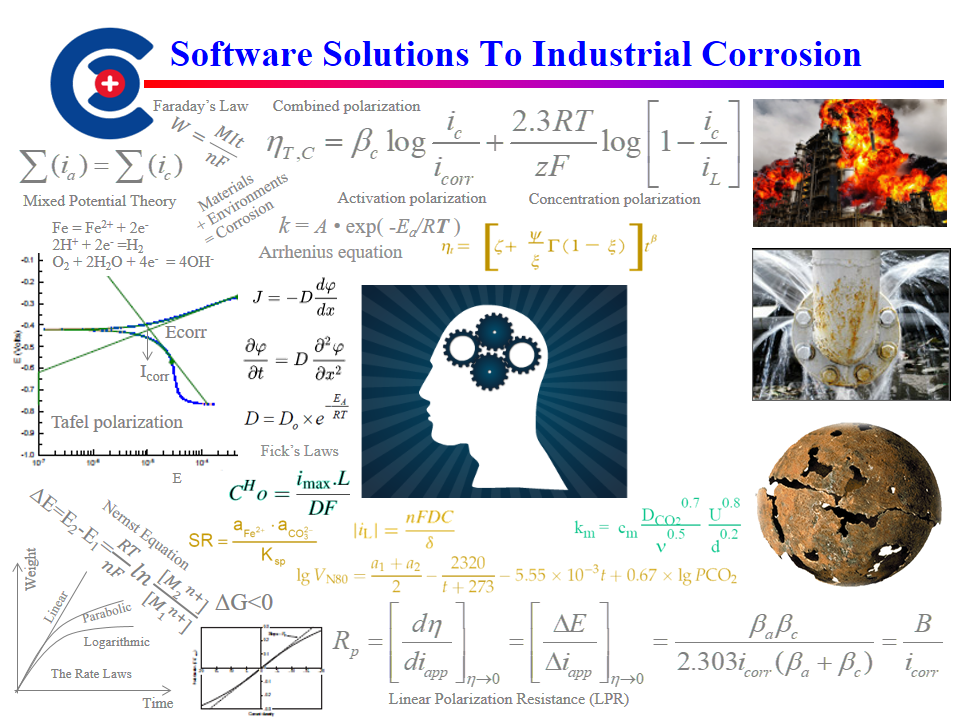

In this course, 47 predictive modeling

software are discussed with their specific applicability to the many

damage mechanisms in API 571, the different types of corrosion,

corrosion in the various industries, and corrosion in different service

environments. This training course is available for in-house training, on-demand, online, and on-Webex/on-ZOOM training worldwide. It can also be customized to meet the specific needs of your organization.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Course Outline | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1. Introduction To Corrosion

1.1 Definitions of Corrosion

1.2 Different Types of Corrosion

2.

Corrosion Testing vs. Predictive Modeling

2.1 Corrosion Testing vs. Predictive Modeling

2.3 The Need for Predictive Modeling

3.

Predictive Modeling Software Solutions To Damage Mechanisms in API 571

4.

Predictive Modeling Software Solutions To Different Types of

Corrosion

4.1

Software Solutions To General Attack or Uniform Corrosion

4.2

Software Solutions To Galvanic Corrosion

4.3

Software Solutions To Pitting Corrosion

4.4

Software Solutions To Crevice Corrosion and Filiform Corrosion

4.5

Software Solutions To CO2/H2S/HAc Corrosion

4.6

Software Solutions To Environmental Cracking: SCC/HIC/SWC/HSC/SSC/SOHIC/SZC/HB/HE

4.7

Software Solutions To Stray Current Corrosion and AC Corrosion

4.8

Software Solutions To Erosion Corrosion and Flow-Accelerated Corrosion (FAC)

4.9

Software Solutions To Caustic Corrosion and Caustic Stress Cracking

4.10

Software Solutions To Naphthenic Acid Corrosion (NAC)

4.11

Software Solutions To Elemental Sulfur Corrosion, High Temperature Sulfidation/Sulfidic Corrosion/H2-H2S

Corrosion

4.12

Software Solutions To Low Temperature Hydrogen Damages (Hydrogen Blistering,

Hydrogen-Induced Cracking,

4.13

Software Solutions To High Temperature Oxidation, Molten Salt Corrosion, High

Temperature Fuel Ash Corrosion

4.14

Software Solutions To High Temperature Creep and Stress Rupture

4.15

Software Solutions To Atmospheric Corrosion

4.16

Software Solutions To Seawater Corrosion

4.17

Software Solutions To Soil Corrosion

4.18

Software Solutions To Concrete Corrosion

4.19

Software Solutions To Sand Erosion

4.20

Software Solutions To Ant Nest Corrosion (Formicary Corrosion)

4.21

Software Solutions To Microbiologically Influenced Corrosion (MIC)

4.22

Software Solutions To Corrosion Under Insulation (CUI) and Fire-Proofing

5.1

Software Solutions To Corrosion in the Oil and Gas Industry

5.2

Software Solutions To Corrosion in the Pipeline Industry

5.3

Software Solutions To Corrosion in Oil Refining, Petrochemical, Chemical

Processing,

5.4

Software Solutions To Corrosion in Marine and Offshore Industry

5.5

Software Solutions To Corrosion in Microelectronics and Semiconductor

Manufacturing Industry

5.6

Software Solutions To Corrosion in Desalination, Water and Waste Water

Industries

5.7

Software Solutions To Corrosion in Public Transportation Industry

5.8

Software Solutions To Corrosion in Automotive and Aerospace Industries

5.9

Software Solutions To Corrosion in Defense and Military Industry

5.10

Software Solutions To Corrosion in Nuclear Waste Transport, Storage, and

Disposal Industry

5.11

Software Solutions To Corrosion in the Building and Construction Industry

5.12

Software Solutions To Corrosion in Public Utility Services

5.13

Software Solutions To Corrosion in Heating, Ventilation, Air conditioning, and

Refrigeration (HVACR) Industry

5.14

Software Solutions To Corrosion in the Solar Power and Thermal Energy Storage

Industry

5.15

Software Solutions To Corrosion in Liquid Cooling Systems for High-Power

Electronics and Data Centers

5.16

Software Solutions To Corrosion in Archaeology, National Heritage, Museums

and Arts Industries

5.17

Software Solutions To Corrosion in General Industry

6. Predictive

Modeling Software Solutions To Different Service Environments

6.1

Software Solutions To

Corrosion in Atmosphere

6.2 Software

Solutions To Corrosion in Waters/Steam

6.3

Software Solutions To

Corrosion in Soils

6.4

Software Solutions To

Corrosion in Concrete

6.5

Software Solutions To Vapor

Phase Corrosion in Closed Systems

6.6

Software Solutions To

Corrosion in Acids

6.7

Software Solutions To

Corrosion Under the Influence of AC and/or Magnetic Fields

6.8

Software Solutions To

Corrosion at High Temperature

7.

Introduction to Extreme Value Statistics (EVS)

8.

Application Examples of EVS‐Compass: Seeing the Bigger Picture

from Limited Data -EVS Extrapolation in Space and in Time

8.1 EVS Extrapolation of Pit Depth from Small Area Samples to Larger

Industrial Structures For Service Life Prediction

8.2 EVS Extrapolation of Pit Depth from Short-Term Test Data For

Long-Term Service

Life Prediction

8.2.1 predicting the time to first leak or perforation

8.3

Applications of EVS Extrapolation in Partial Coverage NDT Inspection

9. End-of-Course Examination

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Why WebCorr|Course Outline|Who Should Attend |Registration |In-House |On-Demand |Online Courses |On Webex|PPT Slides+Testbank |Course List |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Who Should Attend This Corrosion Course | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Design engineers, process engineers, reliability engineers, QA/QC personnel, maintenance and inspection engineers, researchers, and consultants who are concerned with corrosion and are interested in predictive modeling software for solutions to various corrosion challenges they face in their daily work.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Registration for This Corrosion Course | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Click here to register for this corrosion course online, or Click here to download this corrosion course brochure with registration form in PDF format.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In-House Training Corrosion Courses and On-Site Training Corrosion Courses | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

There is no limit to the number of participants required for in-house training corrosion courses. We conduct the in-house training corrosion course at your company's premises worldwide, and at a time convenient to your company.

All our corrosion courses can be seamlessly integrated into your company's Learning Management System (LMS) for continuous education and training of your employees.

WebCorr, protecting people, assets, and the environment from the harmful effect of corrosion. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Online Corrosion Courses and Distance Learning Corrosion Courses | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

All our corrosion courses can be seamlessly integrated into your company's Learning Management System (LMS) for continuous education and training of your employees.

Click here to to register an online corrosion short course.

WebCorr, protecting people, assets, and the environment from the harmful effect of corrosion. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Corrosion Course-On-Demand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Click here to contact us for a quotation for corrosion course-on-demand. WebCorr, protecting people, assets, and the environment from the harmful effect of corrosion. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trainer's Package - PowerPoint Slides and Test Bank (with Solutions) for Trainers, Instructors, Tutors, University Lecturers and Professors | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

If you are involved in teaching or training, you may wish to purchase a complete set of the trainer's package for any of the training courses listed above. The trainer's package comes complete with ready-to-use PowerPoint slides (fully editable) and test bank (with answer keys). These ready-to-use PowerPoint slides contain high quality color photographs, illustrations, animations, audio and video clips. The test banks contain questions conveniently grouped into four categories: (1) true or false, (2) multiple choice, (3) calculation, and (4) reasoning and open-ended discussions. These trainer's packages are suitable for structured training programs for professional development and educational courses at different levels (from basics to advanced) and durations (from 6 hrs to 40 hours). These are exactly the same packages that WebCorr use to deliver our current training courses. The one-time lump sum fee allows your organization to use the training package and also modify it. For example, your organization may modify the course contents and re-name/re-brand the course under your organization’s name. WebCorr only retains the copyright of the original PowerPoint slides and test banks.

WebCorr also offers Train-the-Trainers program. Your company can send one or more core team members to WebCorr for intensive training to become competent trainers in any of the corrosion courses of your choice. The trainer's package is fully included in the Train-the-Trainers program.

WebCorr, protecting people, assets, and the environment from the harmful effect of corrosion. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Why WebCorr|Course Outline|Who Should Attend |Registration |In-House |On-Demand |Online Courses |On Webex|PPT Slides+Testbank |Course List |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Copyright © 1995-2024. All rights reserved. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

This

3-day course covers 47 predictive modeling software solutions to industrial

corrosion. Attendees will learn how predictive modeling software can

provide smart solutions to materials selection, process optimization,

condition assessment, maintenance planning, and corrosion life

prediction in various industries.

This

3-day course covers 47 predictive modeling software solutions to industrial

corrosion. Attendees will learn how predictive modeling software can

provide smart solutions to materials selection, process optimization,

condition assessment, maintenance planning, and corrosion life

prediction in various industries.

If you are concerned with corrosion in your company, in-house training or on-site training is a great solution to train a group of employees from design, production, operation, quality assurance, inspection and maintenance, and technical sales and support on corrosion control and corrosion prevention technology. The contents of all our corrosion courses can be customized to fit your organization's needs.

If you are concerned with corrosion in your company, in-house training or on-site training is a great solution to train a group of employees from design, production, operation, quality assurance, inspection and maintenance, and technical sales and support on corrosion control and corrosion prevention technology. The contents of all our corrosion courses can be customized to fit your organization's needs.

All our corrosion short courses are available for instructor-led live online training, self-paced online learning or offline distance learning. You can start a self-paced online corrosion course at any time and learn at your own comfortable pace and schedule, whenever and wherever you are. You have around-the-clock access to interactive and media-rich course materials, virtual labs, course instructions, course assignments, and course assessments. Learning support is provided directly by our NACE certified Corrosion Specialist via email. Instructor-led live online training can also be conducted for your organization. For those who do not have ready access to internet, we can send you our online course materials on a CD-ROM or DVD or USB memory stick for offline distance learning.

All our corrosion short courses are available for instructor-led live online training, self-paced online learning or offline distance learning. You can start a self-paced online corrosion course at any time and learn at your own comfortable pace and schedule, whenever and wherever you are. You have around-the-clock access to interactive and media-rich course materials, virtual labs, course instructions, course assignments, and course assessments. Learning support is provided directly by our NACE certified Corrosion Specialist via email. Instructor-led live online training can also be conducted for your organization. For those who do not have ready access to internet, we can send you our online course materials on a CD-ROM or DVD or USB memory stick for offline distance learning. All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you (on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house or on-site corrosion training program.

All our publicly scheduled corrosion short courses are conducted once a year. However, you do not need to wait for one year if you have missed any of the publicly scheduled corrosion courses as we have this unique corrosion course-on-demand scheme: we will conduct the course just for you (on an one-on-one basis) or for a small group from your company at a time and in a location convenient to you. This option costs significantly less than a full-scale in-house or on-site corrosion training program.