|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series ISO15156-Compass®: Modeling and Prediction of in-situ pH, Region of Environmental Severity, and Susceptibility to Sulfide Stress Cracking (SSC) of Carbon and Low Alloy Steels

High-Value Software Solutions to Costly Corrosion

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins |

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training

& Support |

CorrCompass |

|

|

Overview of ISO15156-Compass |

|

|

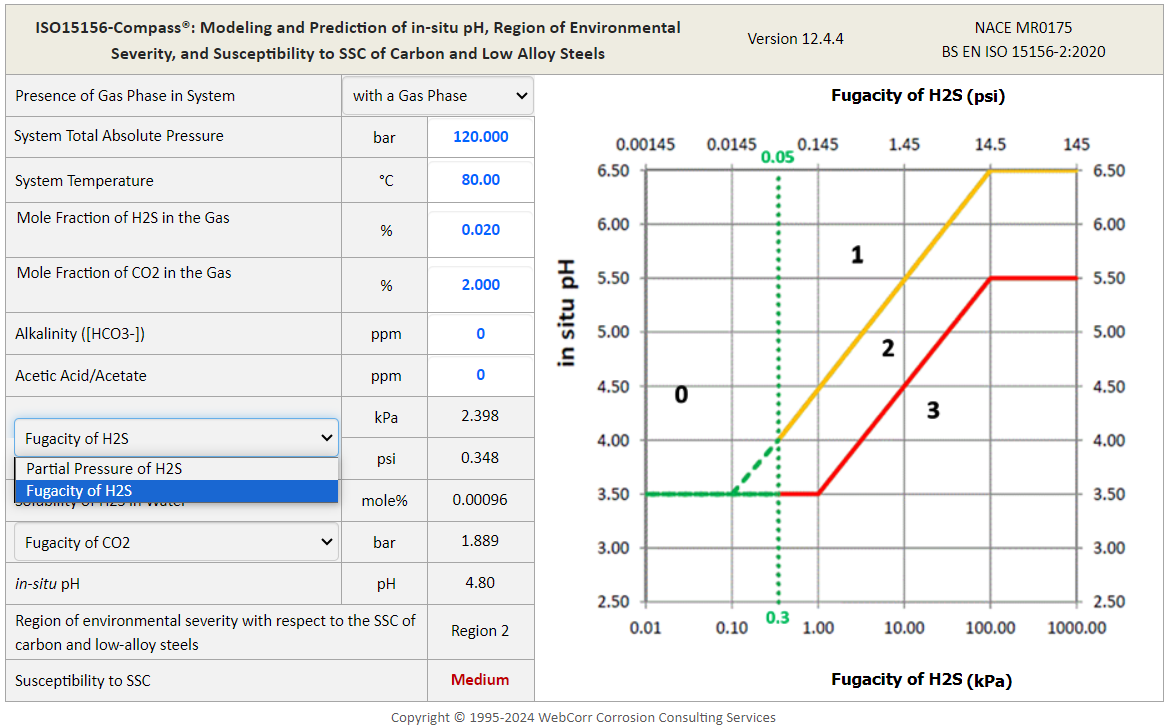

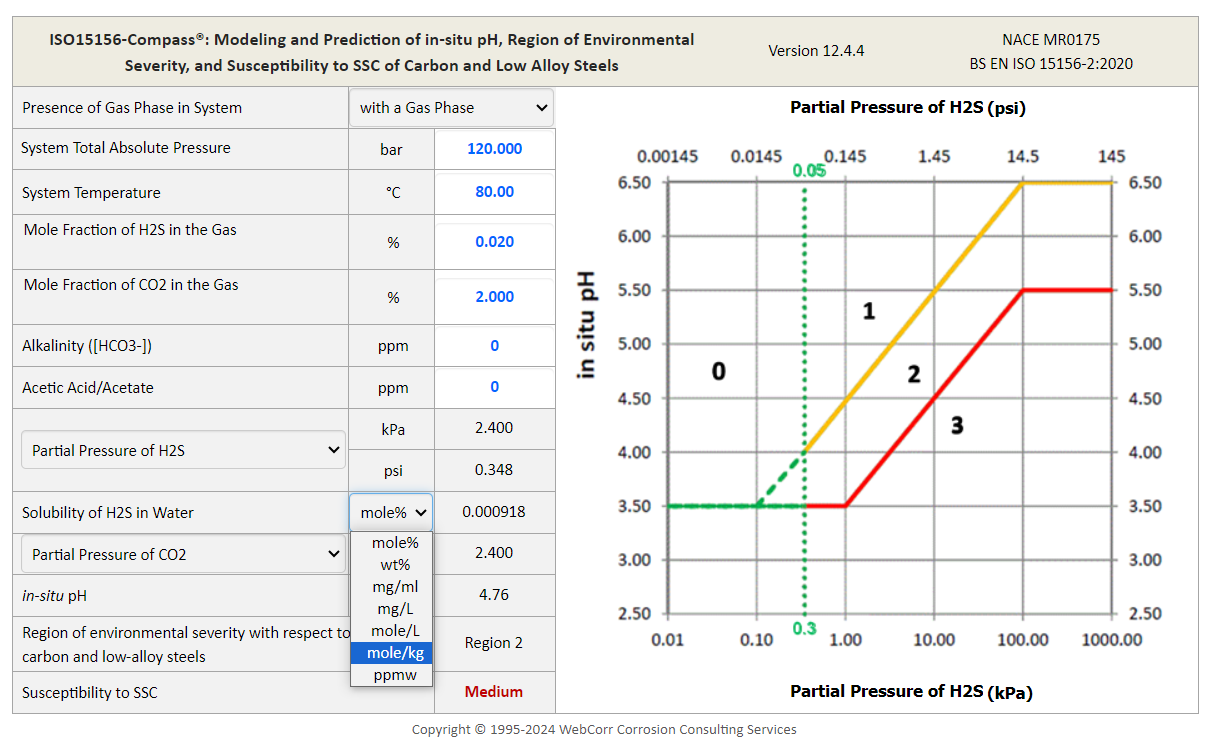

ISO15156-Compass models and predicts in-situ pH, regions of environmental severity, and susceptibility to sulfide stress cracking (SSC) of carbon and low alloy steels in accordance with NACE MR0175 / BS EN ISO 15156-2:2020 "Petroleum and natural gas industries - Materials for use in H2S-containing environments in oil and gas production, Part 2: Cracking-resistant carbon and low-alloys steels, and the use of cast irons".

ISO15156-Compass models the effects of H2S partial pressure, CO2 partial pressure, system temperature, alkalinity of produced fluid, and acetic acid/acetate on the in-situ pH, solubility of H2S, regions of environmental severity, and the susceptibility to sulfide stress cracking (SSC) of carbon and low alloy steels. Using ISO15156-Compass is as easy as 1-2-3: (1) select the production system (gas-free liquid system or system with a gas phase), (2) enter the production data, (3) review the modeling and prediction results

Figures below show the screen shots.

Figure 1 Modeling and Prediction of in-situ pH, Regions of Environmental Severity, and Susceptibility to SSC

Figure 2 ISO15156-Compass works for both gas-free liquid systems and systems with a gas phase

Figure 3 ISO15156-Compass gives user the option to use fugacity instead of partial pressure

in the modeling and prediction of in-situ pH, region of environmental

severity, and SSC susceptibility.

Figure 4 ISO15156-Compass predicts the solubility of H2S in water

under the prevailing operating conditions.

Since the publication of ISO 15156-2:2015/Cir.1:2017 Annex C, users may

employ H2S fugacity rather than partial pressure for characterization of

the severity of the production environment. It is understood that these

modern sour severity metrics may better represent the true chemical

activity of H2S at high total pressures, compared to the traditional

partial pressure metric. ISO15156-Compass gives users the option to use

H2S fugacity or H2S partial pressure in the assessment of the

environmental severity. ISO15156-Compass software also predicts the

dissolved H2S in the water phase under the prevailing operating

conditions, with a user preferred H2S concentration unit: mole%, wt%,

mg/ml, mole/L, mole/kg, and ppmw.

Click here to contact us for licensing details and experience the power of ISO15156-Compass. |

|

|

ISO15156-Compass, the software solution to SSC prediction and materials selection for oil and gas production systems. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2025. WebCorr Corrosion Consulting Services. All rights reserved. |