|

Home | Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |

Corrosion Modeling Software and Corrosion Prediction Software Series NH3Compass®: Modeling and Prediction of Corrosion in Ammonia Production and Services Version 9.22

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|

|

Why WebCorr |

Performance Guarantee |

Unparalleled Functionality |

Unmatched Usability |

Any Device Any OS |

Free Training & Support |

CorrCompass |

|

|

Overview and Application Examples of NH3Compass |

|

|

Anhydrous ammonia is manufactured by combining hydrogen and nitrogen in a molar ratio of 3:1, compressing the gas and then cooling it to about -27°F (-33°C). Corrosion at high temperatures in H2 and N2 environment include: (1) high temperature hydrogen attack (HTHA), (2) creep and stress rupture, and (3) nitriding. Corrosion at low temperatures include: (1) ammonia stress corrosion cracking (SCC), (2) ammonia carbamate formation, (3) general corrosion, (4) galvanic corrosion and other damage mechanisms.

NH3Compass is the only device and OS independent software tool on the market for the modeling and prediction of corrosion in ammonia production, storage, transport, and other services. NH3Compass is a cloud-based software that works on any device running any OS without the need for users to install or download anything. Designers, OEM engineers, consultants, operation personnel, maintenance and inspection engineers can quickly and accurately determine:

(1) the risk of high temperature hydrogen attack (HTHA) under the prevailing operating condition; (2) the risk of creep and stress rupture under the prevailing operating condition; (3) the nitriding potential and nitriding depth under the prevailing operating condition; (4) the corrosion rates for metals and alloys in anhydrous liquid ammonia; (5) the galvanic effect of coupling different metals and alloys in anhydrous liquid ammonia; (6) the risk of ammonia stress corrosion cracking (SCC) under the prevailing operating condition; (7) the risk of ammonia carbamate formation; (8) materials selection as affected by the changes in process parameters.

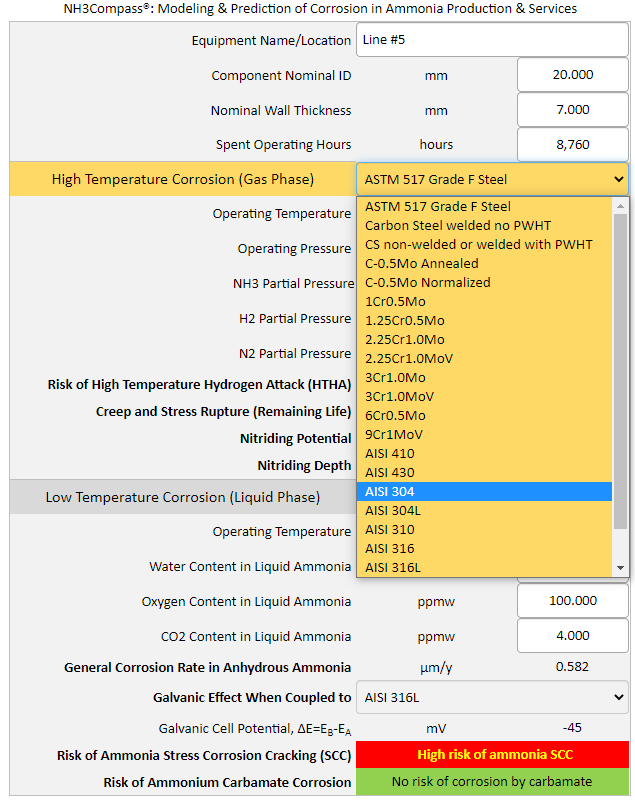

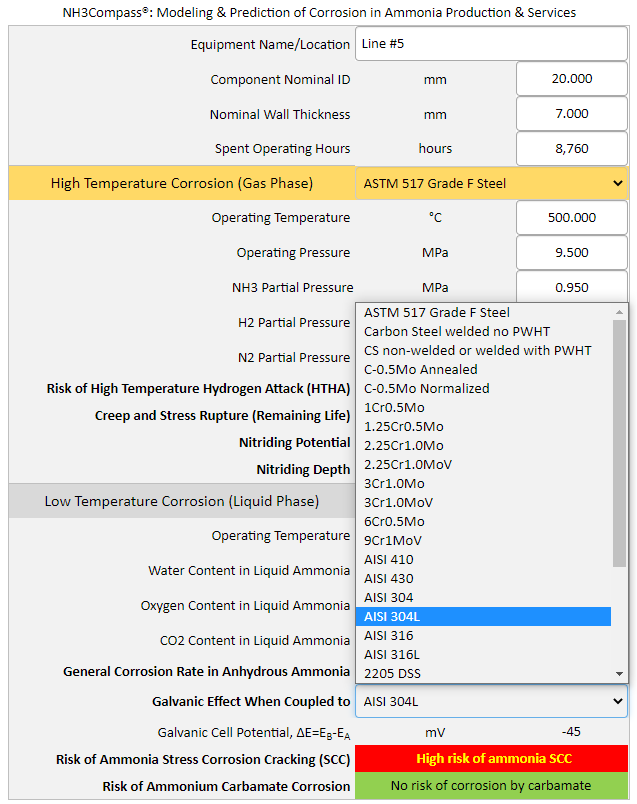

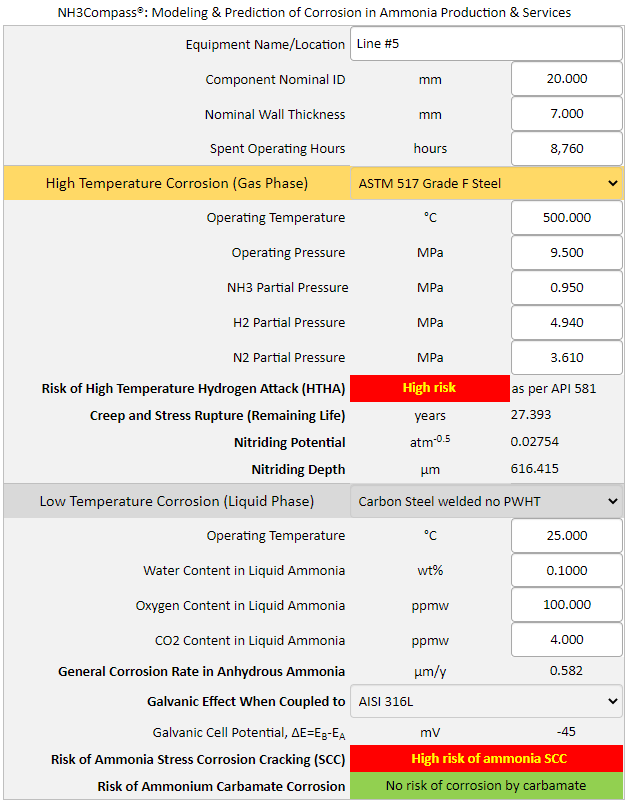

Figure 1 NH3Compass predicts corrosion at high temperatures and low temperatures.

Figures 2 and 3 below show the materials selection for both high temperature and low temperature services in ammonia production, storage, and transport.

Figure 2 Materials selection for high temperature services in ammonia production.

Figure 3 Materials selection for low temperature services in ammonia production, storage, and transport.

The powerful applications of NH3Compass are truly unlimited in engineering design, materials selection, process optimization, inspection and maintenance, modeling and prediction of corrosion

in ammonia production, storage, transport, and other services.

Click here to contact us for licensing details and experience the power of NH3Compass. |

|

NH3Compass, giving you the right directions in the Modeling and Prediction of Corrosion in Ammonia Production, Storage, and Transport. |

|

|

Home | Contact Us | PDF |

Copyright © 1995-2025. All rights reserved. |

Under the prevailing operating conditions

shown in Figure 1 above, the selected metallurgy, ASTM A517 Grade F steel, is predicted to have high risk of high temperature hydrogen attack (HTHA), as per API 581 risk ranking methodology. The remaining life due to creep and stress rupture is 27.393

years. The selected metallurgy is susceptible to nitriding under the the prevailing operating conditions,

with a nitriding potential of 0.02754 atm-0.5 and nitriding

depth of 616.415

µm. At low temperatures, the selected carbon steel (no PWHT) is highly susceptible to ammonia stress corrosion cracking (SCC) under the specified operating conditions. When the carbon steel is coupled to another metal, AISI 316L, NH3Compass predicts the galvanic cell potential of -45 mV than can cause accelerated corrosion of the anode metal. NH3Compass predicts that there is no risk of corrosion caused by ammonia carbamate formation, as shown in Figure 1.

Under the prevailing operating conditions

shown in Figure 1 above, the selected metallurgy, ASTM A517 Grade F steel, is predicted to have high risk of high temperature hydrogen attack (HTHA), as per API 581 risk ranking methodology. The remaining life due to creep and stress rupture is 27.393

years. The selected metallurgy is susceptible to nitriding under the the prevailing operating conditions,

with a nitriding potential of 0.02754 atm-0.5 and nitriding

depth of 616.415

µm. At low temperatures, the selected carbon steel (no PWHT) is highly susceptible to ammonia stress corrosion cracking (SCC) under the specified operating conditions. When the carbon steel is coupled to another metal, AISI 316L, NH3Compass predicts the galvanic cell potential of -45 mV than can cause accelerated corrosion of the anode metal. NH3Compass predicts that there is no risk of corrosion caused by ammonia carbamate formation, as shown in Figure 1.