|

Consulting | Training | Expert Witness | Failure Analysis | Design Review | Corrosion Test | Corrosion Software | Protective Coatings | Materials Selection | Cathodic Protection | >>> | |||

|

- Identification, Assessment and Prediction

Anytime Anywhere Any Device Any OS No USB dongles No installation No Browser Plug-ins

|

|||

|

Features and Functions of SC-Compass

|

|||

|

Stray current corrosion refers to corrosion resulting from stray current - the current flowing through paths other than the intended circuit. In the corrosion literature, non-standard terms used by some authors include stray current electrolysis and electrolytic corrosion. Among the many different types of corrosion, stray current corrosion is probably the most misused term by unqualified corrosion consultants worldwide who literally refer to any corrosion phenomenon beyond their comprehension as stray current corrosion. This mis-diagnosis often results in significant financial losses and safety lapses for facility owners and operators.

Accurate identification of stray current corrosion requires a sound understanding of all types of corrosion. A qualified corrosion consultant (NACE certified Corrosion Specialist) can tell the differences among the different types of corrosion. Stray current corrosion is fundamentally different from other (non-stray current) types of corrosion in that stray current corrosion is an electrolysis process. In the electrolysis process, the external current (stray current) alone drives metal atoms into electrolyte as water-soluble ions. The environmental factors such as oxygen concentration, cathode-to-anode area ratio, chloride, and pH that are so critical to natural corrosion processes are no longer relevant. The extent of damage or loss of metal is directly proportional to the magnitude of stray current leaving the structure at the point of discharge. Stray current corrosion will be concentrated at certain location that leads to the lowest electrical resistance in the current circuit.

SC-Compass is developed by NACE certified corrosion specialists with both BEng and PhD degrees in corrosion. It is the only device and OS independent software tool on the market for identification, assessment and prediction of Stray Current Corrosion and AC Corrosion in underground pipelines, rail transit systems, reinforced concrete structures, boats/ships/vessels, and other metallic structures carrying electrical current. Designers, engineers, consultants, maintenance and inspection personnel can quickly identify, assess and quantify the impact of stray current corroison and AC corrosion on the remaining life of their structures/components anytime, anywhere, on any device running any OS without the need to install or download anything. SC-Compass is developed in full complaince with the latest editions of BS EN and NACE standards relating to stray current corrosion and AC corrosion. SC-Compass has answers to all the frequently asked questions below and more:

Frequently Asked Questions on Stray Current Corrosion:

Frequently Asked Questions on AC Corrosion:

Overview and Application Examples of SC-Compass

Figures below show the screen shots of SC-Compass. There are 6 modules in SC-Compass for 6 groups of structures:

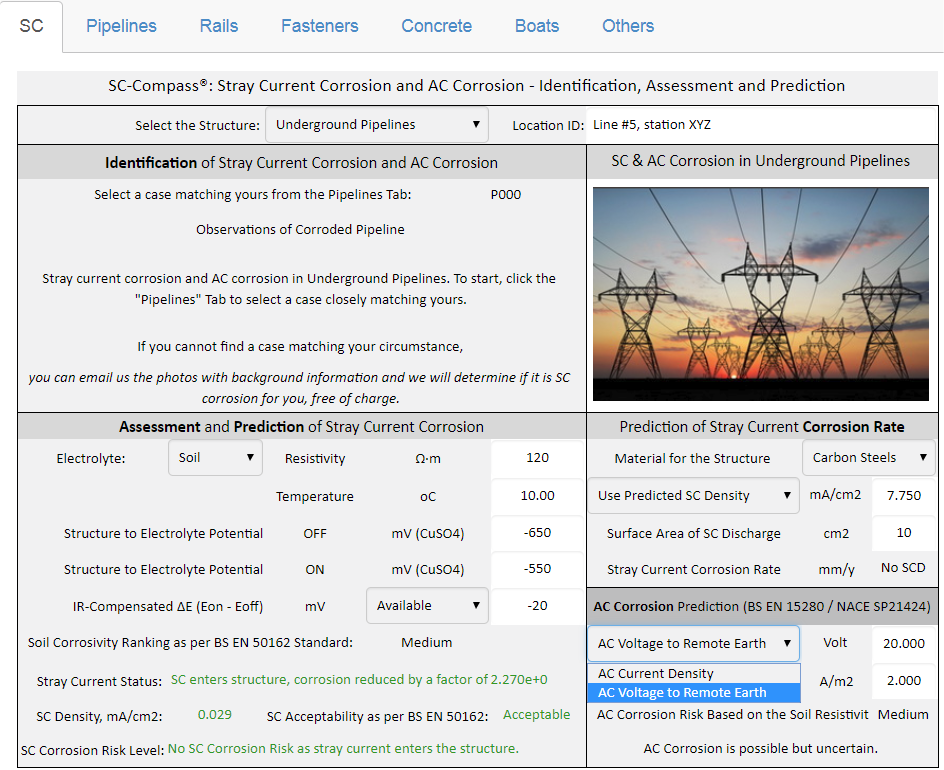

The main screen in SC-Compass has 5 zones:

Figure 1 Overview of SC-Compass

Users of SC-Compass start by selecting the type of structure from the dropdown list: Rails Rail Fasteners Re-inforced Concrete Structures Underground Pipelines Boats, Ships and Vessels Other Metallic Structures

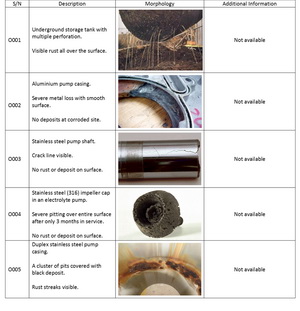

After selecting the structure, users simply click the corresponding Tab and select a case from the built-in database that closely matches the users' circumstance based on the description and morphology of the corroded structure as demonstrated below.

Figure 2 shows the database under "Others" Tab for "Other Metallic Structures". An user selected a case closely matching his/her circumstance. Identification of stray current corrosion and AC corrosion, and relevant comments on the user selected case are displayed in Zone 1, with the representative image showing the corroded morphology dispalyed in Zone 2, as shown in Figure 3.

Figure 2 Stray Current Corrosion and AC Corrosion Identification

Figure 3 Identification of Stray Current Corrosion and AC Corrosion for User Selected Case

SC-Compass determines that the selected case is NOT stray current corrosion and displays comment on this case:

"Stray current corrosion is an electrolysis process and as such, it will not produce heavy rust scales, pinhole type pitting, or any form of cracking."

If an user cannot find a case closely matching his/her own situation in the database, the user can email the photos with background information to WebCorr. Our NACE certified Corrosion Specialists will then examine the photos and analyze the information to determine if it is stray current corrosion or AC corrosion. This consulting service is free of charge to licensed users of SC-Compass during the entire licensing period. The savings in consulting fee can be worth many times of the license fee.

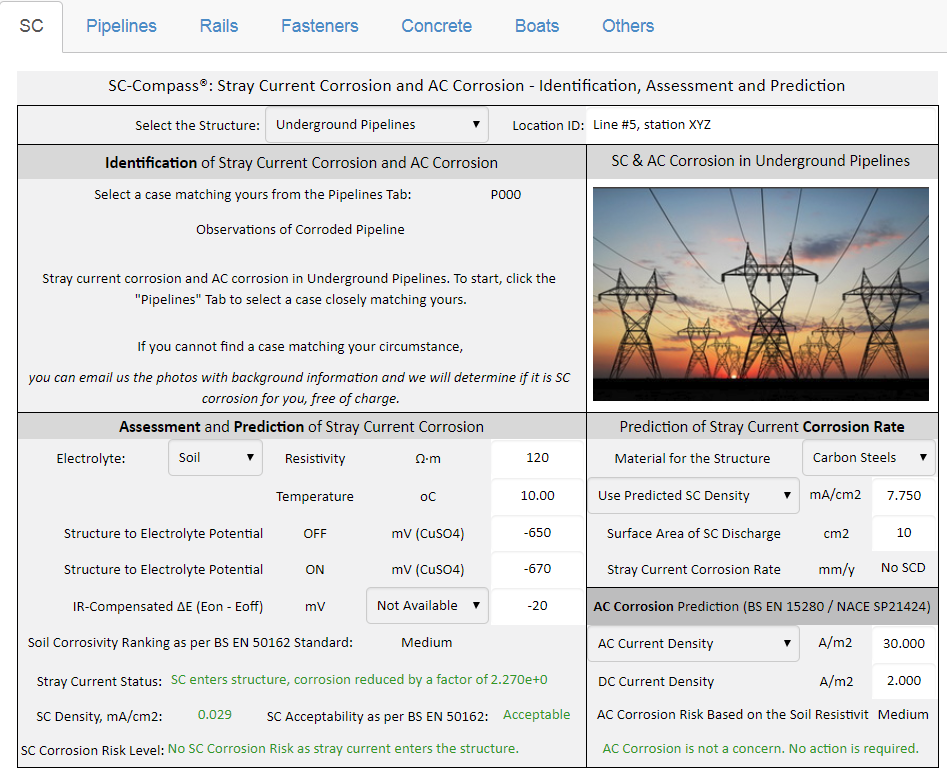

Assessment and prediction of stray current corrosion in SC-Compass are carried out in accordance with relevant international standards such as BS EN 50162 for DC stray current corrosion, and BS EN 15280/NACE SP21424 standards for AC corrosion.

In Zone 3, users need to select the electrolyte from the dropdown list: Soil, Water, Concrete. The electrical resistivity (in the unit of Ω.m) of the selected electrolyte is then entered. The structure to electrolyte potentials with respect to a copper sulphate reference electrode are required to assess the stray current status, stray current corrosion risk level and stray current acceptability as per BS EN 50162 standard.

Figure 3 Stray Current Corrosion and Assessment and Prediction

In Figure 3 above, an user entered the following values as inputs: Soil resistivity: 120 Ω.m Temperature: 10oC Structure to electrolyte potential (OFF): -650 mV Structure to electrolyte potential (ON): -550 mV IR-compensated potential shift ΔE: Not Available (if set to "Available", the entered value will be used for the assessment)

Based on the user inputs, SC-Compass predicts that stray current is entering the structure and reducing the corrosion rate by a factor of 2.27. SC-Compass also computes the amount of stray current in the structure and this is determined to be 0.029 mA/cm2.

The stray current acceptability as per BS EN 50162 is determined to be "Acceptable" and the stray current corrosion risk levle is determined to be "No SC Corrosion Risk as stray current enters the structure".

In Zone 4, the stray current corrosion rate prediction shows "No SCD", - meaning "No Stray Current Discharge" and therefore no stray current corrosion. Stray current corrosion ONLY occurs at the point of discharge. At the point of entry, there is no corrosion.

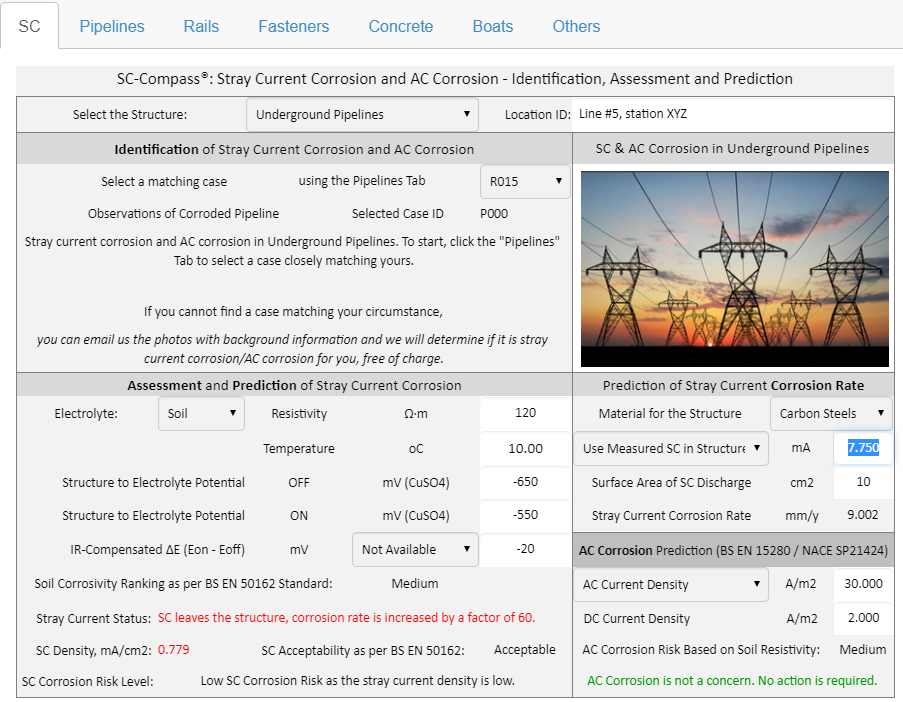

Figure 4a Stray Current Corrosion Rate Calculation from Predicted SC Density

Note that in Zone 3 of Figure 4a above, the input for Structure to Electrolyte potential (ON) has changed to "-550", as a result, SC-Compass predicts that stray current is leaving the structure and increasing the corrosion rate by a factor of 60.29. The amount of stray current is predicted to be 0.779 mA/cm2.

Zone 4 is for the prediction of stray current Corrosion Rate. For the inputs parameters shown in Figure 4a, the stray current corrosion rate predicted by SC-Compass is 9.044 mm per year for carbon steels. If an user measured the stray current in the structure and the surface area over which the stray current discharges, the measured data can be entered for the calcualtion of the stray current corrosion rate by selecting "Use Measured SC in Structure" from the dropdown list, as shown in Figure 4b below. Here, the user enter "7.750" mA as measured stray current in the structure and "10" cm2 as the surface area over which the stray current discharges. The calculated corrosion rate based on the measured data is 9.002 mm per year.

Figure 4b Stray Current Corrosion Rate Calculation from Measured Stray Current

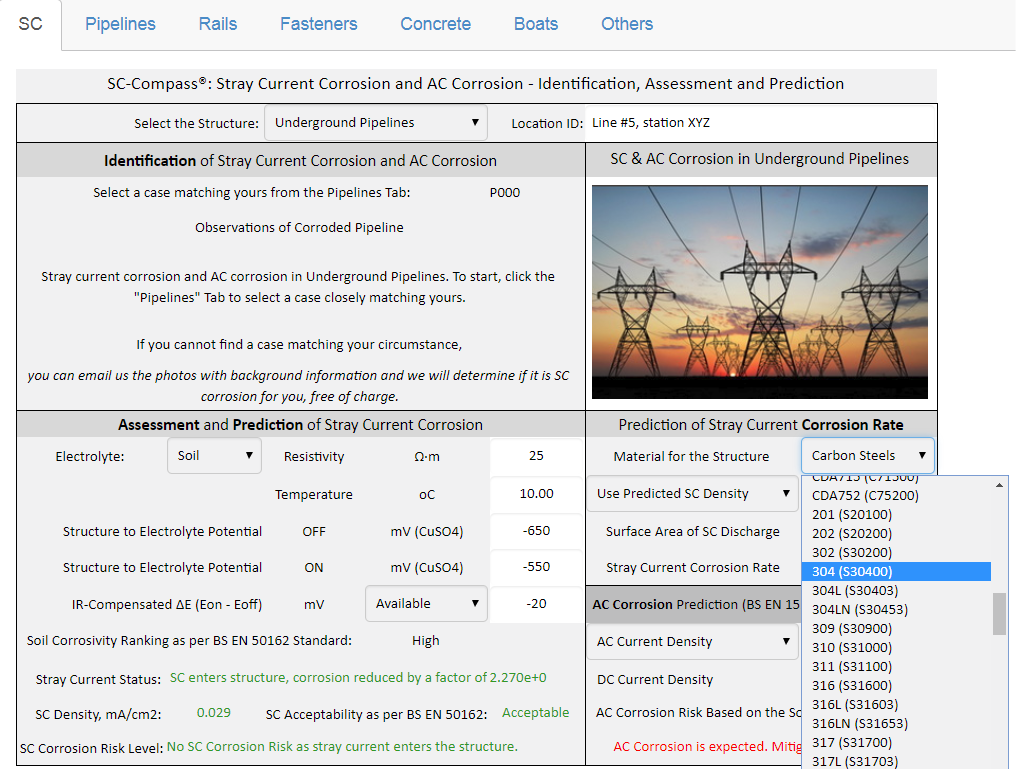

The stray current corrosion rate in mm per year is computed for about 200 metals and alloys (Figure 4c). If you cannot find the metal or alloy in the database, email us the grade of your alloy and we will update the datbase within 24 hours after receiving your request.

Figure 4b Stray Current Corrosion Rate Calculation from Measured Stray Current

Zone 5 is for AC Corrosion Prediction and Assessment For underground pipelines under the influence of induced AC current, the risk of AC corrosion is assesed in accordance with the latest editions of BS EN 15280 and NACE SP 21424 standards. In Zone 5, users can select either AC current density or AC voltage with respect to remote earth from the dropdown list (Figure 5a) for assessment and prediction of AC corrosion. The DC current density is required only if users selected "AC current density" from the dropdown list as the assessment criteria (Figure 5b). SC-Compass takes into consideration of the AC current density to DC current density ratio as per BS EN and NACE standards.

Figure 5a Assessment and Prediciton of AC Corrosion Using AC Current Density and DC Current Density

Figure 5b Assessment and Prediciton of AC Corrosion Using AC Voltage to Remote Earth

The powerful applications of SC-Compass in rail transit systems, civil structures, underground pipelines, boats, ships and vessels are truly unlimited in enginnering design, materials evaluation and selection, remaining life prediction, trouble-shooting and failure analysis. Contact us for licensing details. |

|||

|

SC-Compass, giving you the right directions in Managing Stray Current Corrosion |

|||

|

Home | Contact Us | PDF |

Copyright © 1995-2022. WebCorr Corrosion Consulting Services. All rights reserved. |

||

SC-Compass®: Stray Current Corrosion

and AC Corrosion

SC-Compass®: Stray Current Corrosion

and AC Corrosion